Sorting Conveyor Manufacturer

Conveline Rollers is a well-known name in India as a leading sorting conveyor manufacturer, supplier, and exporter, offering advanced material handling solutions for diverse industries. Our automated sorting conveyor systems are designed to sort, organize, and distribute goods with unmatched efficiency and speed. Built to meet the growing demands of logistics, e-commerce, distribution centers, and manufacturing plants, these systems are engineered for seamless performance even in high-volume operations. Our sorting conveyors use smart sensors, advanced software, and reliable mechanical components to detect the size, weight, shape, color, or destination of each item. Based on these parameters, the system automatically redirects products to their appropriate path or station. Whether you need basic diverting or complex multi-lane sorting, Conveline Rollers provides customizable solutions designed to your operational needs.

Manufacturers of conveyor sortation systems that are perfect for improving productivity and providing smooth workflow in retail warehouses, parcel hubs, and manufacturing plants. From streamlining order fulfillment to reducing manual labor, they help businesses scale operations with precision and reduced cost. Designed for long-term durability and minimal maintenance, our systems support continuous operation with low energy consumption and high ROI. Conveline Rollers’ sortation conveyors are a smart investment for businesses seeking to upgrade their logistics with automation and efficiency-driven results.

Automated Sortation Conveyor Systems

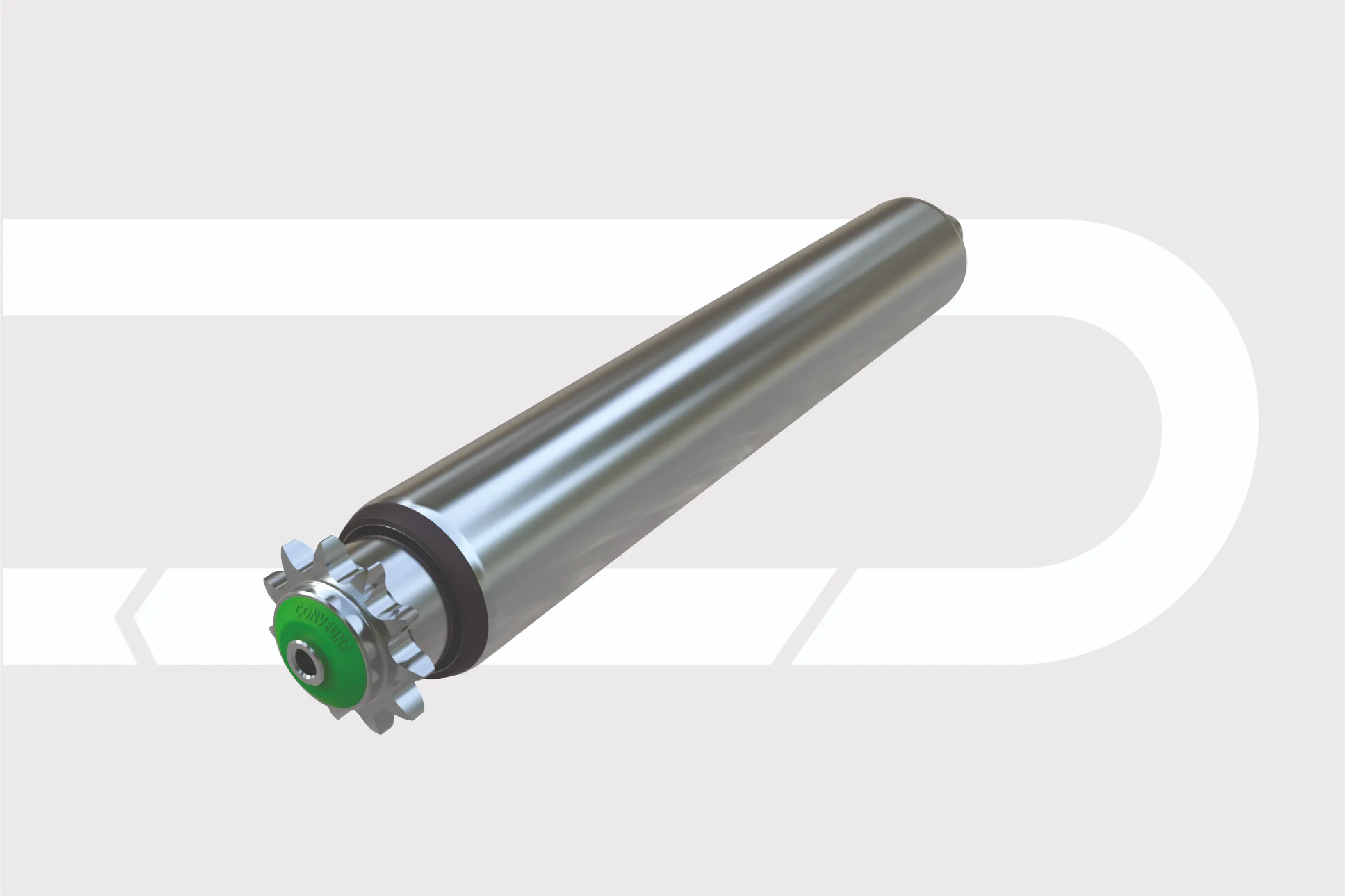

Our advanced automated sortation conveyor systems are designed to simplify and speed up product handling. These systems are essential for sorting and routing items from one conveyor line to another, ensuring smooth and organized flow within warehouses, distribution centers, and manufacturing facilities. Engineered and customized to meet specific operational needs. The setup typically includes induction systems, merges, and sortation diverts, which work together to accurately identify, track, and direct products to the correct destination. This ensures faster processing and reliable order fulfillment.

Our automated sortation conveyor systems serve as the backbone of the material handling process. While conveyors move items through different zones, the sortation system smartly separates products based on size, shape, or shipping destination into specific lanes. This level of automation not only boosts efficiency but also helps reduce manual labor and sorting errors. With a seamless connection of conveyors and sorting units, Conveline Rollers provides fully integrated solutions that optimize workflow and improve overall operational performance. Our systems are designed for long-term use, delivering dependable performance even under the most demanding industrial conditions.

Application in the Food Processing Industry

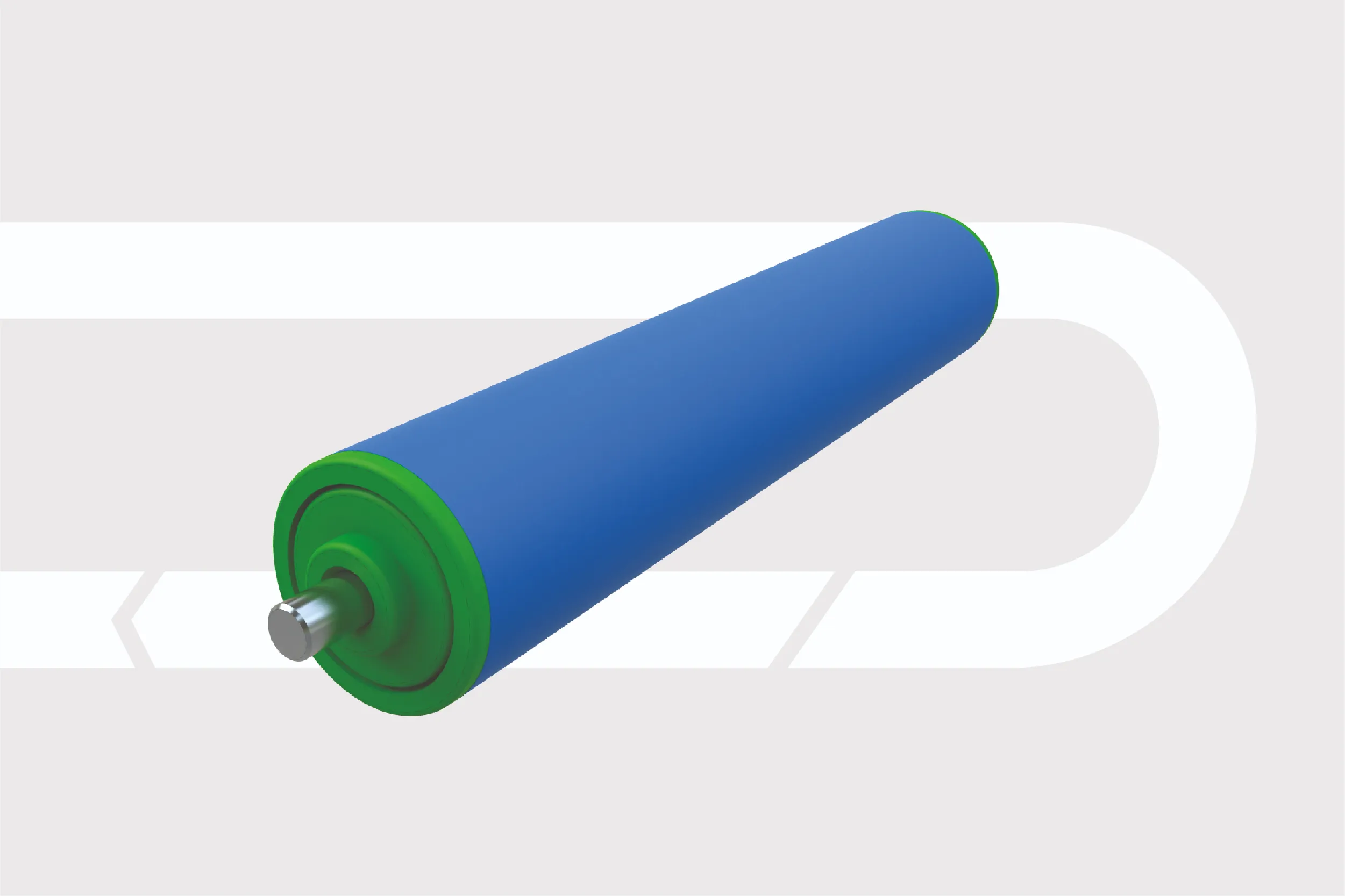

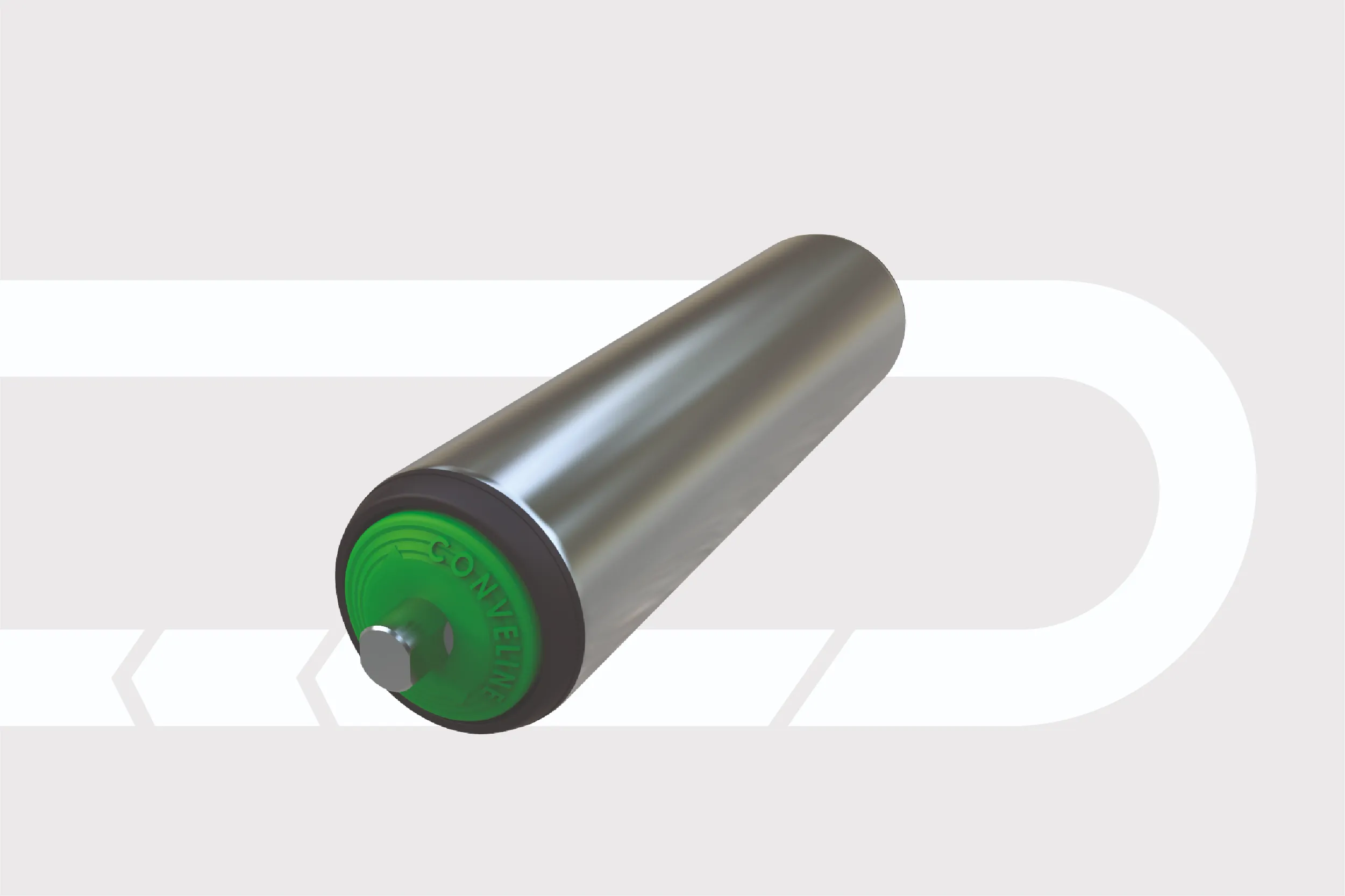

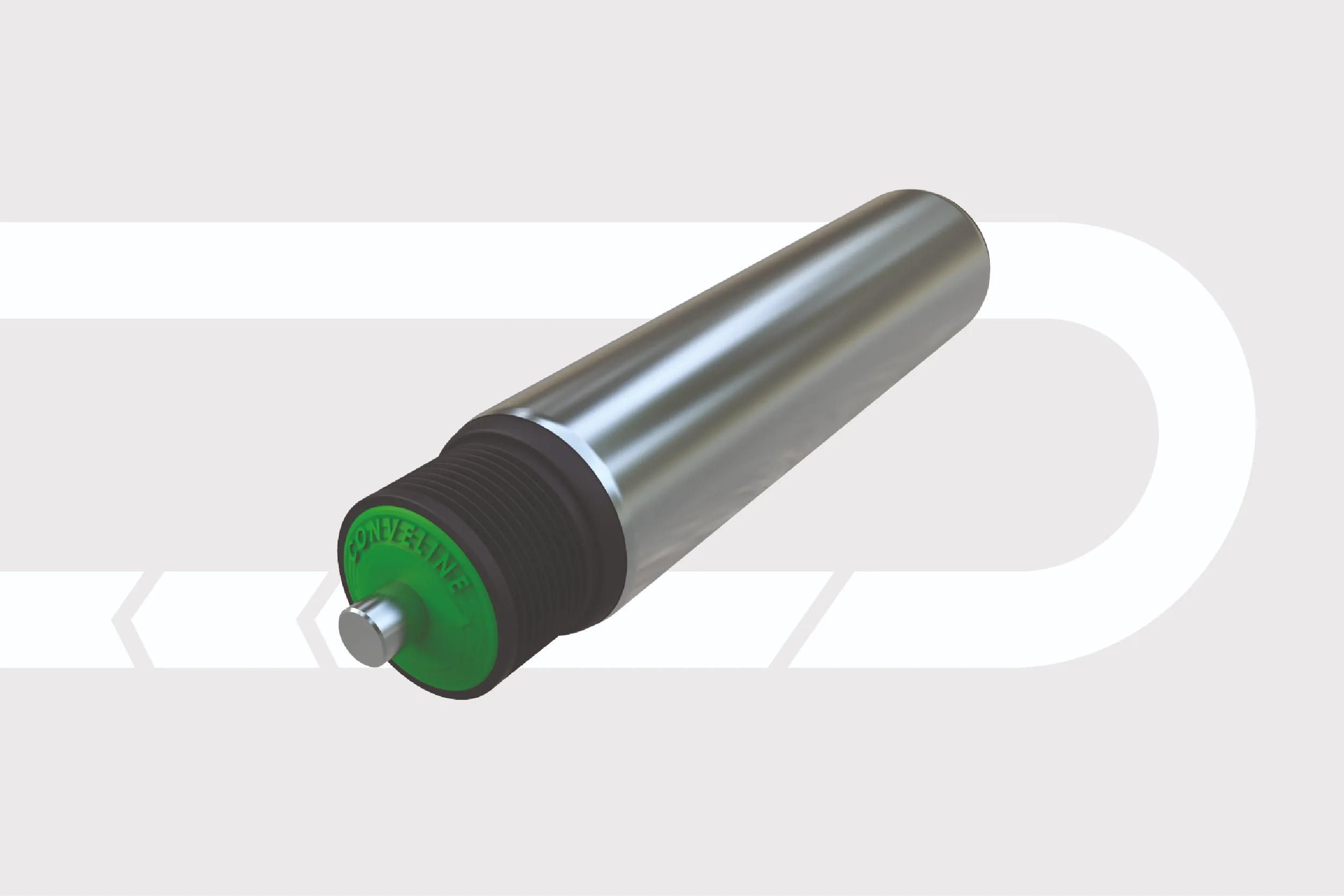

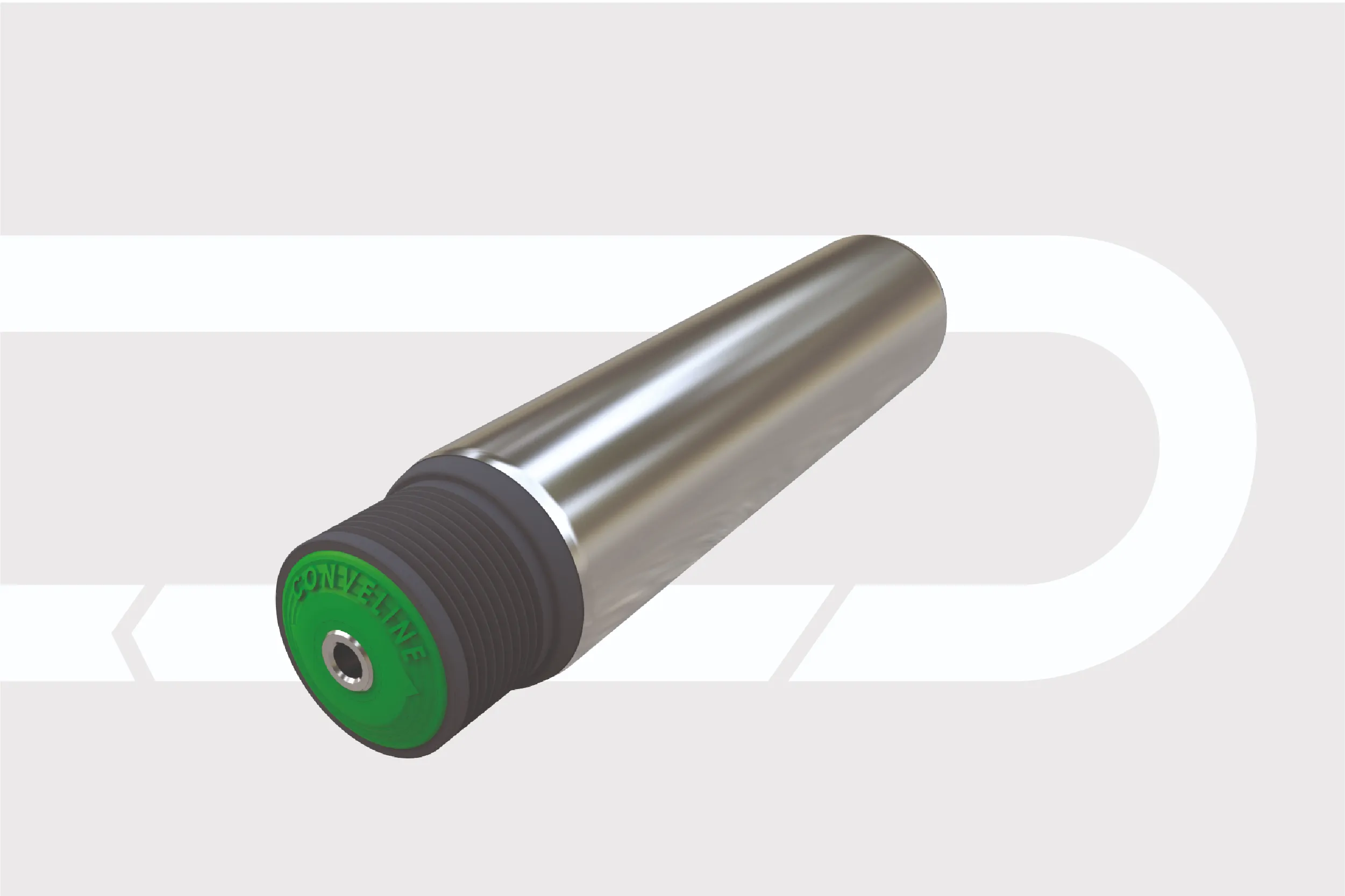

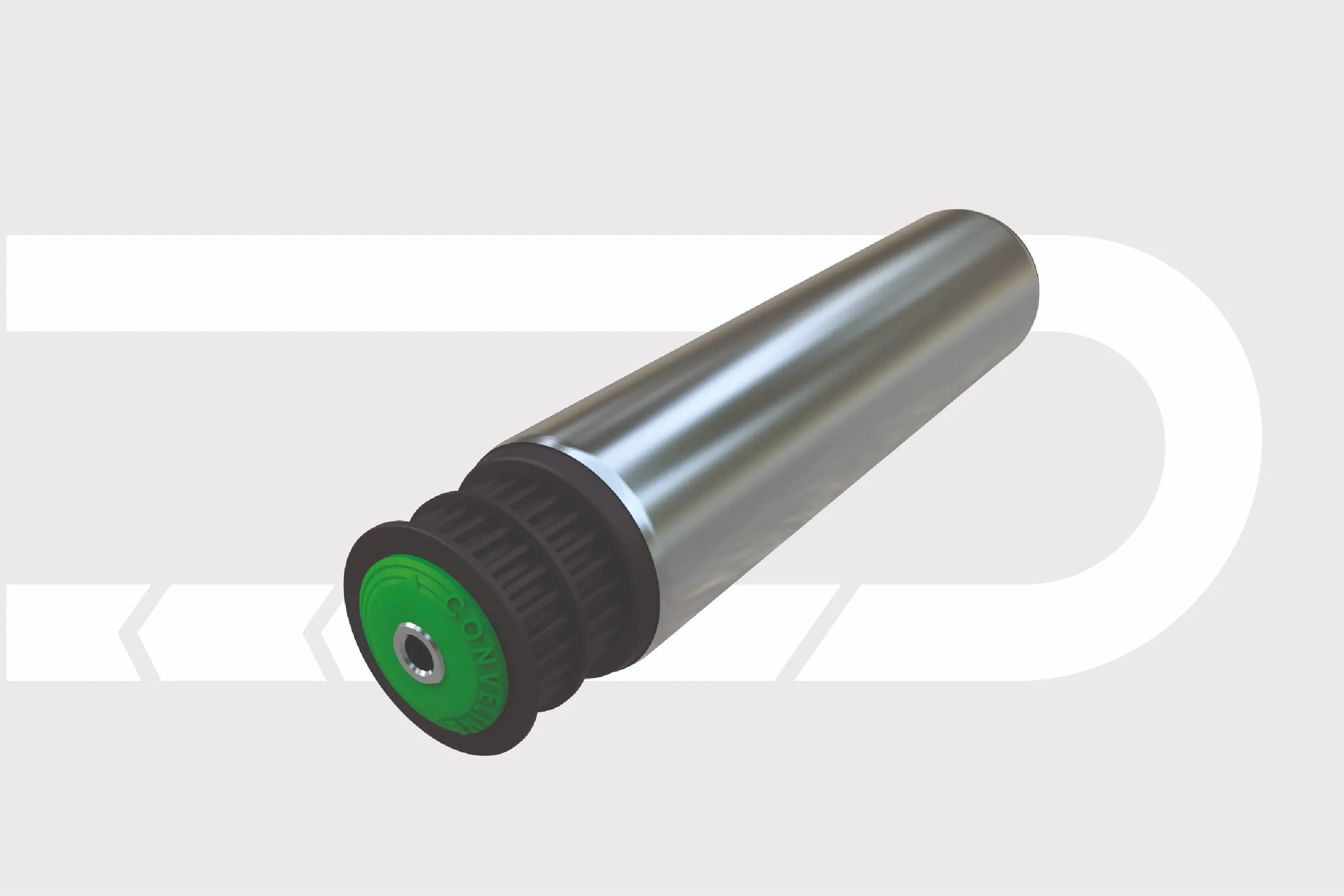

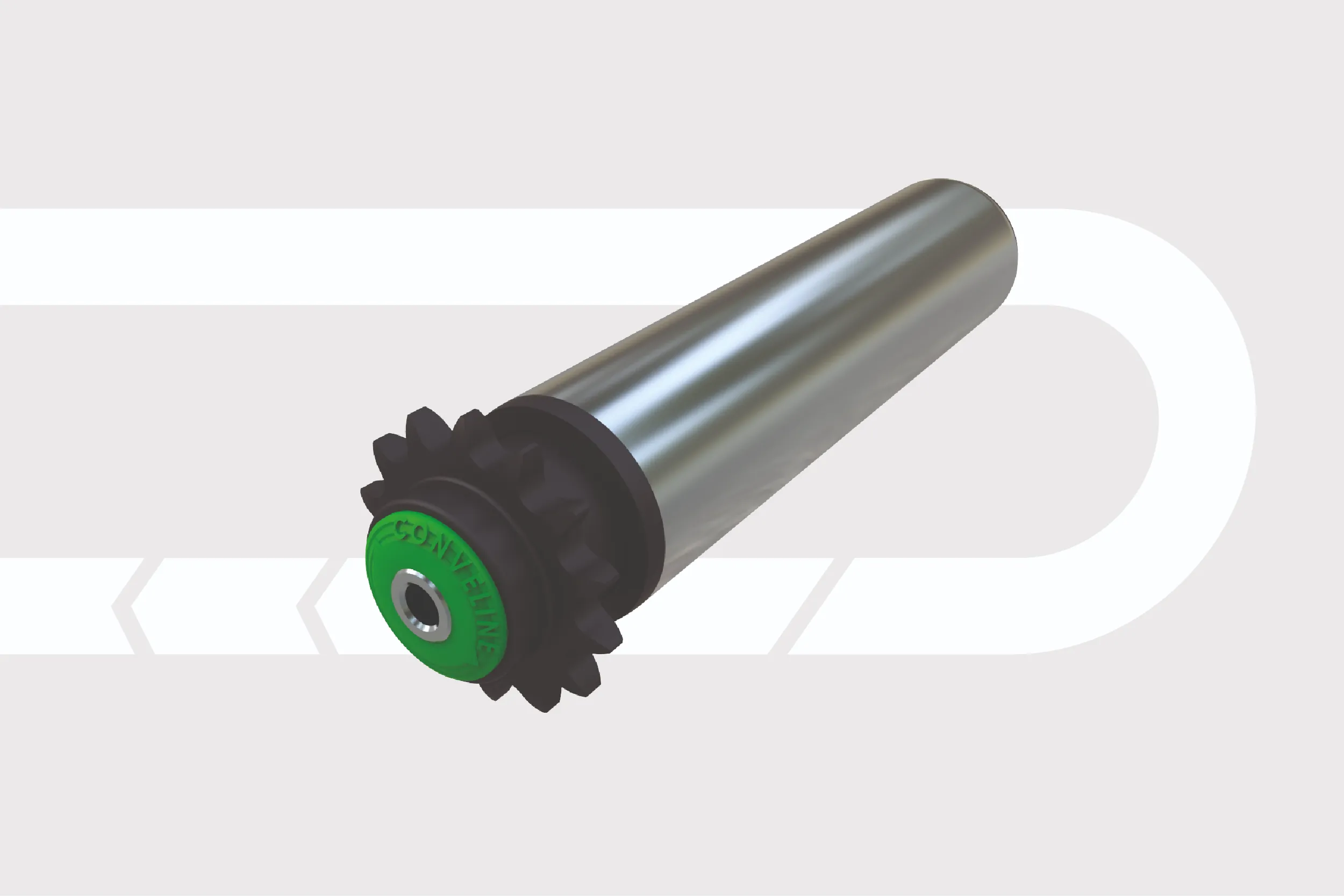

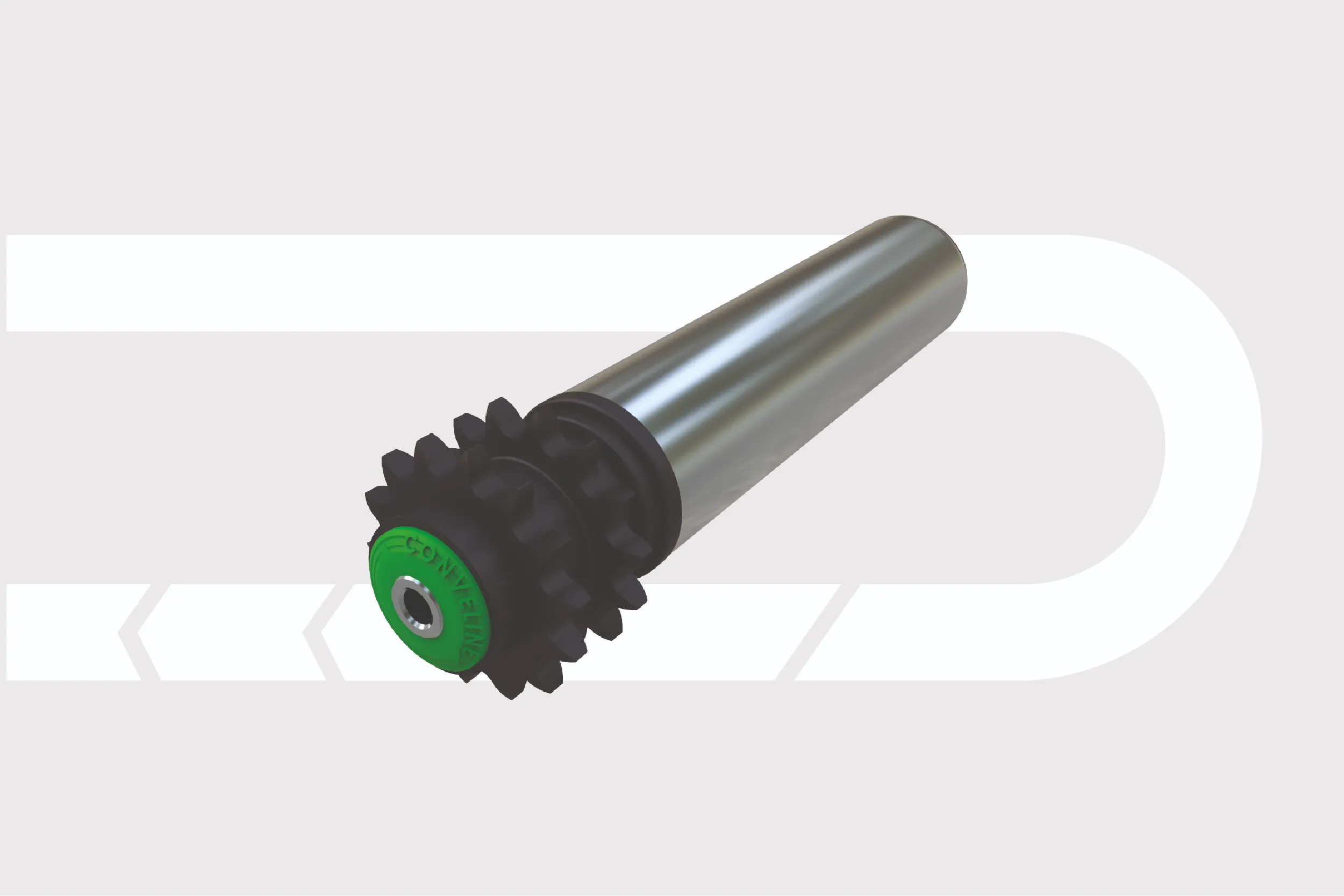

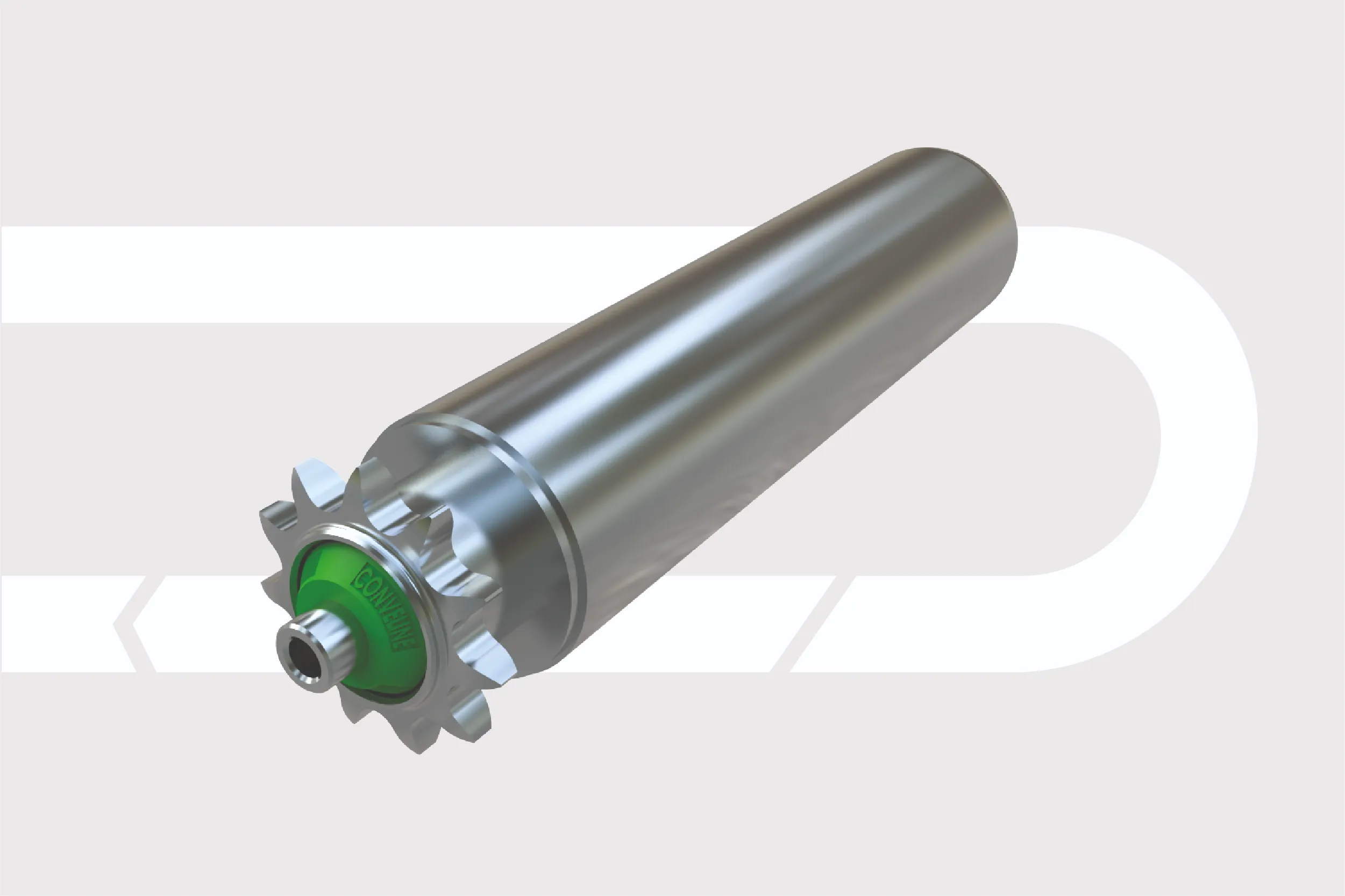

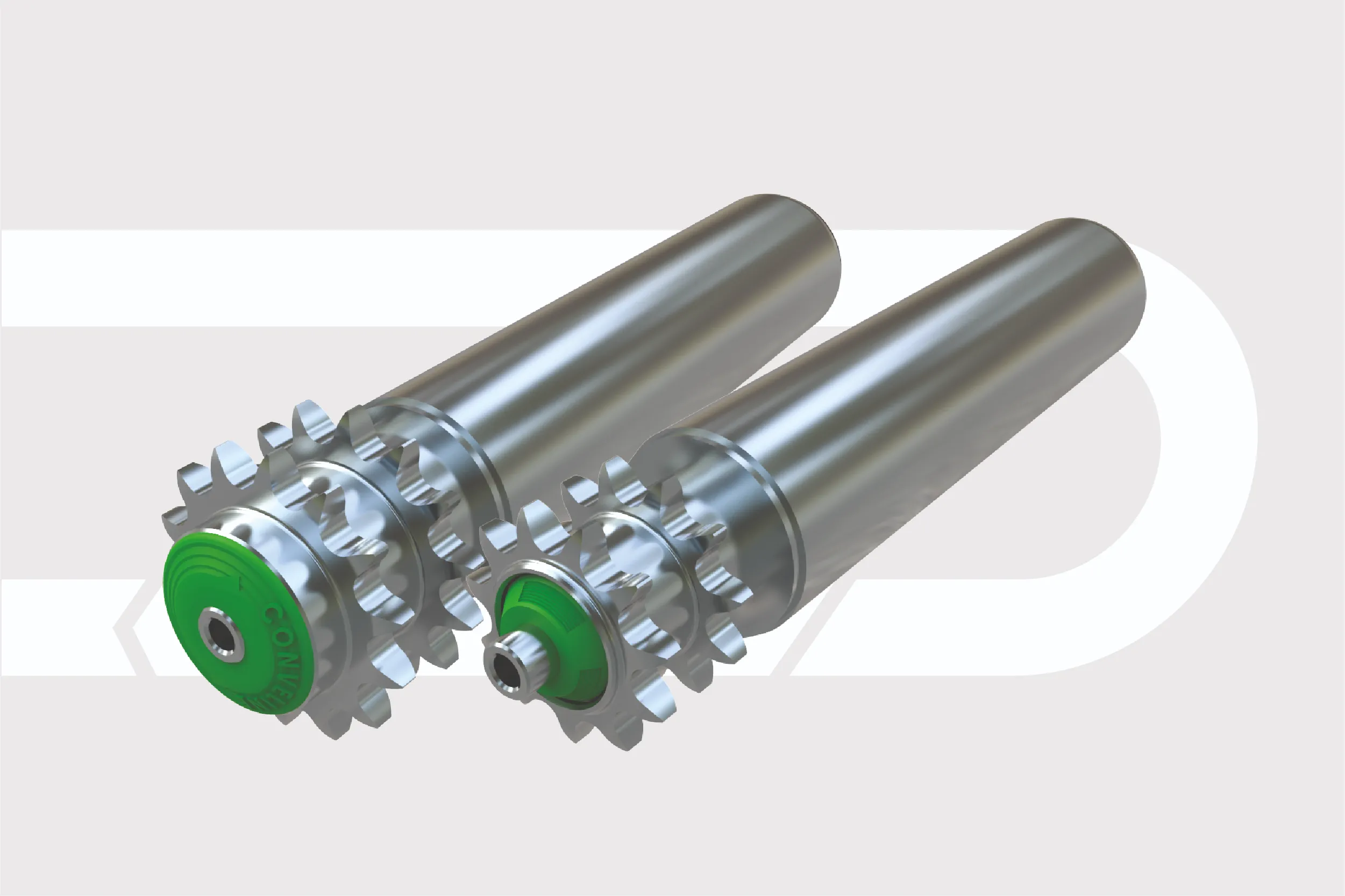

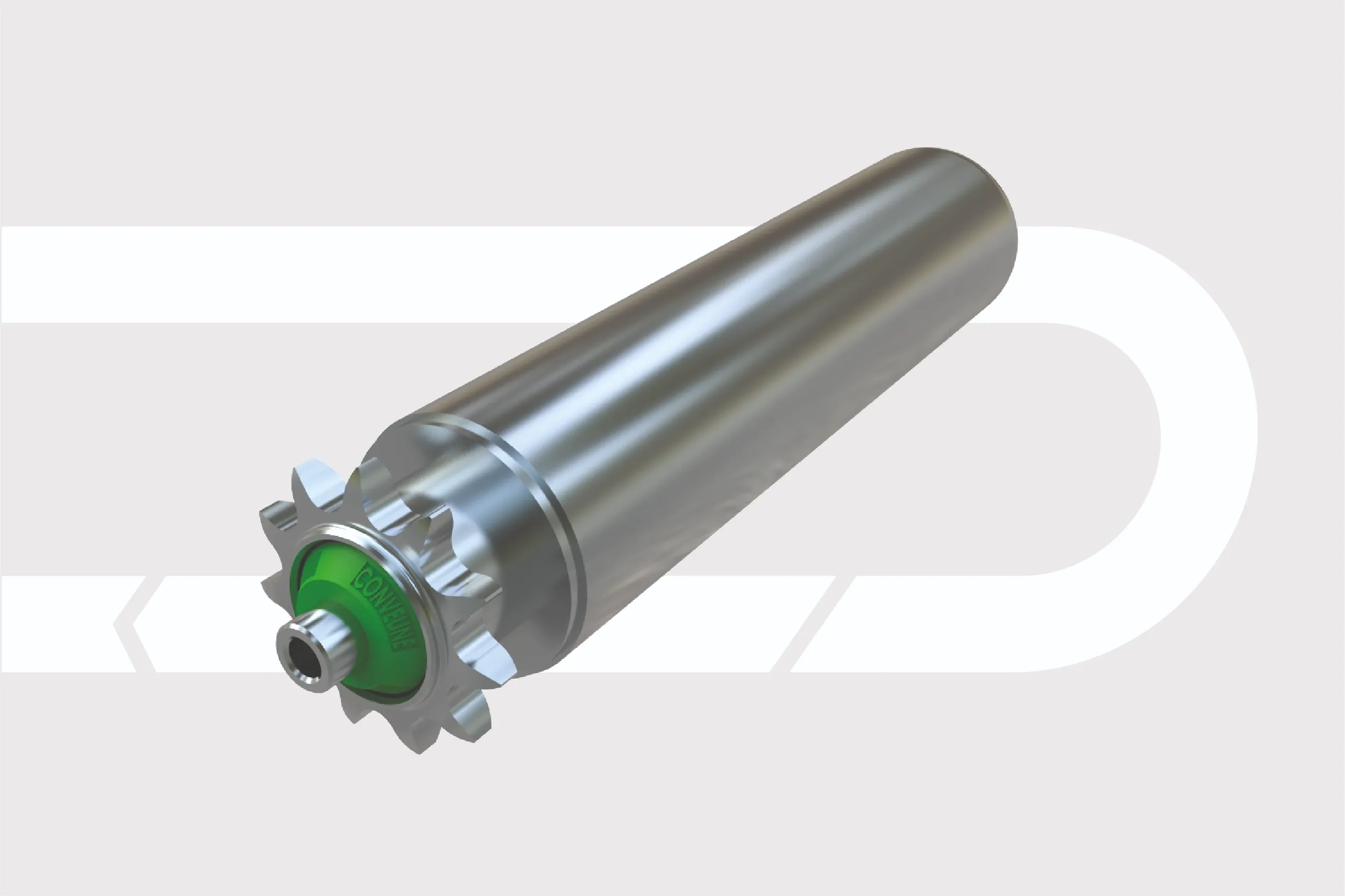

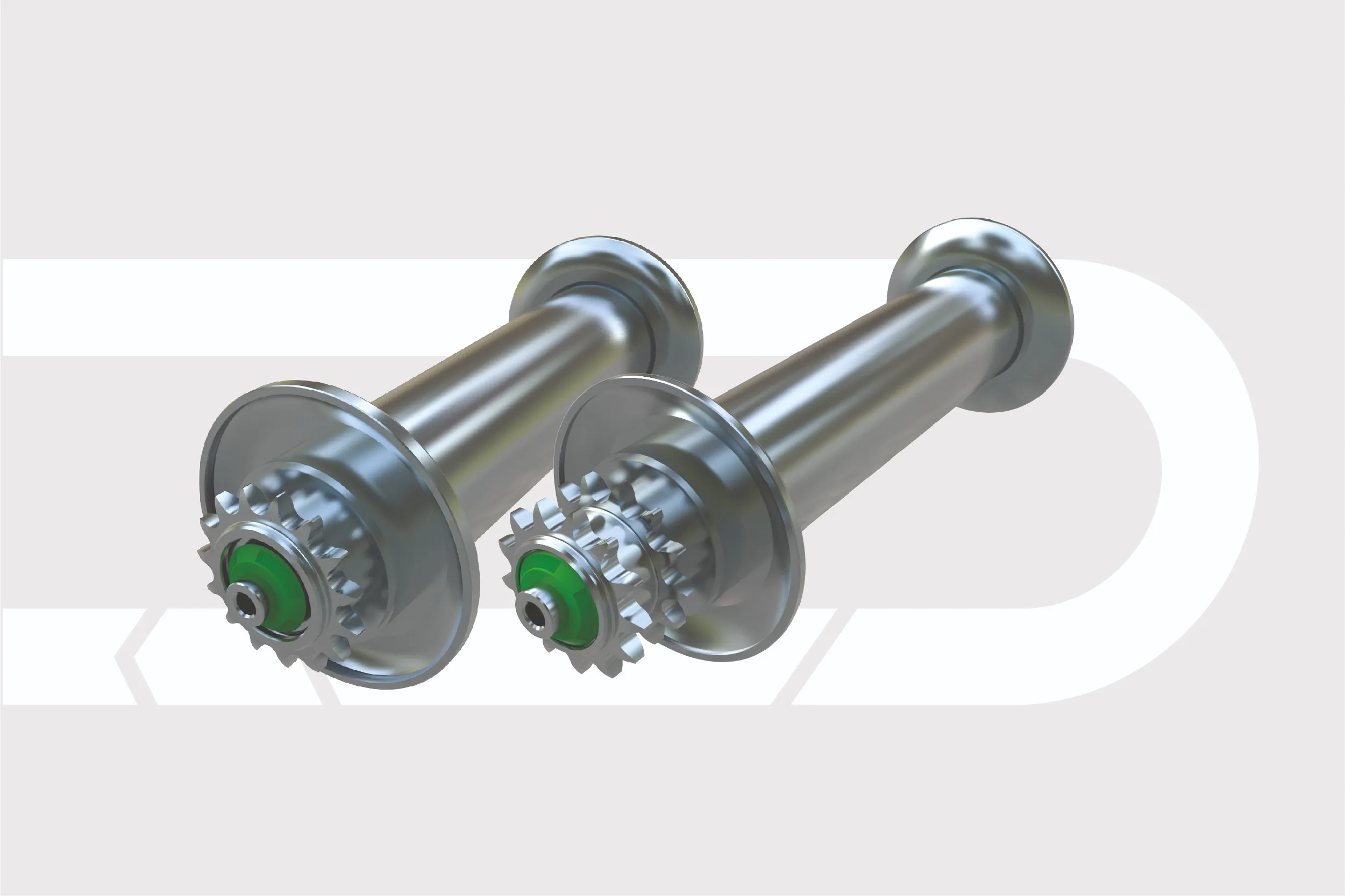

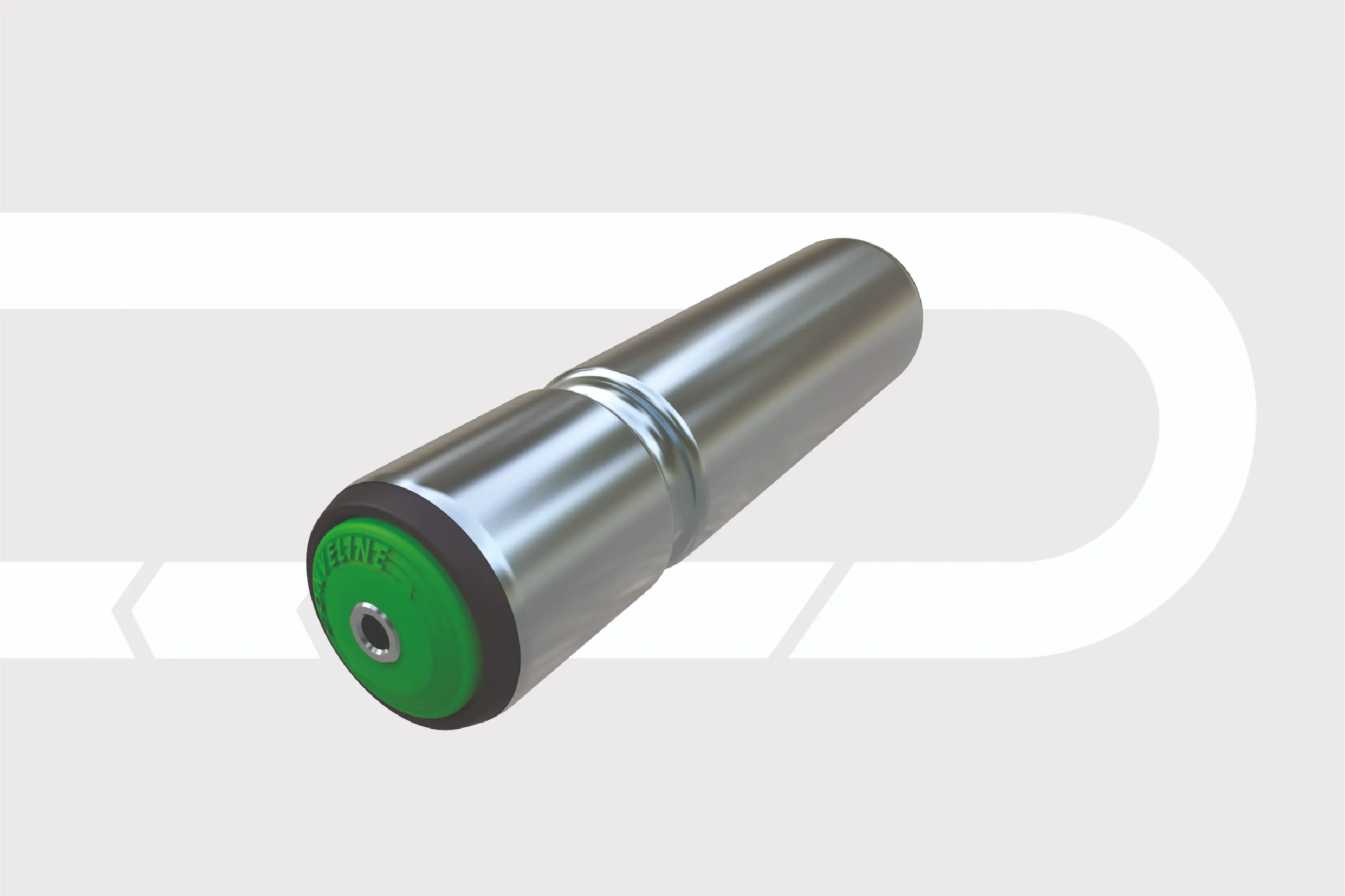

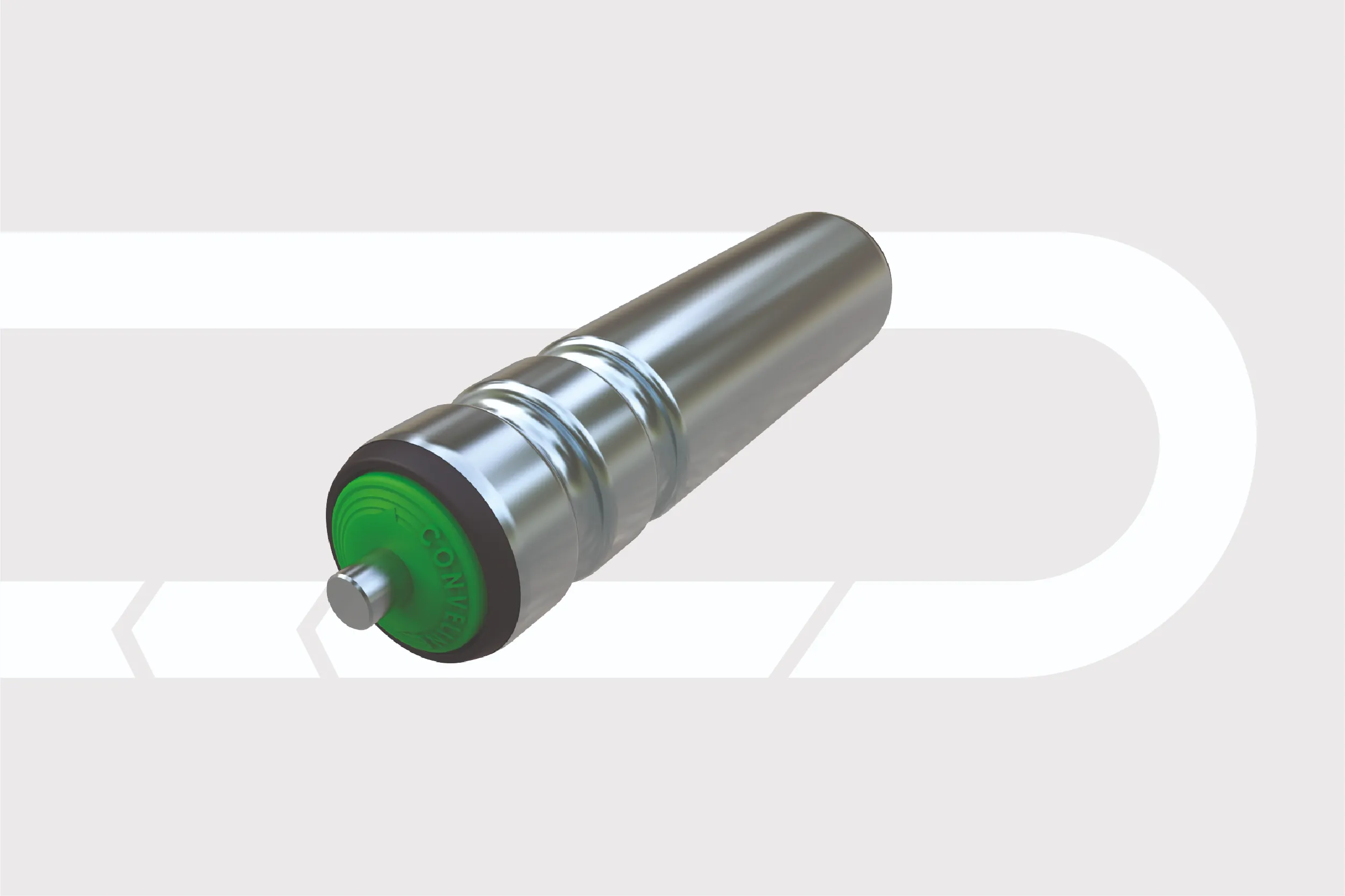

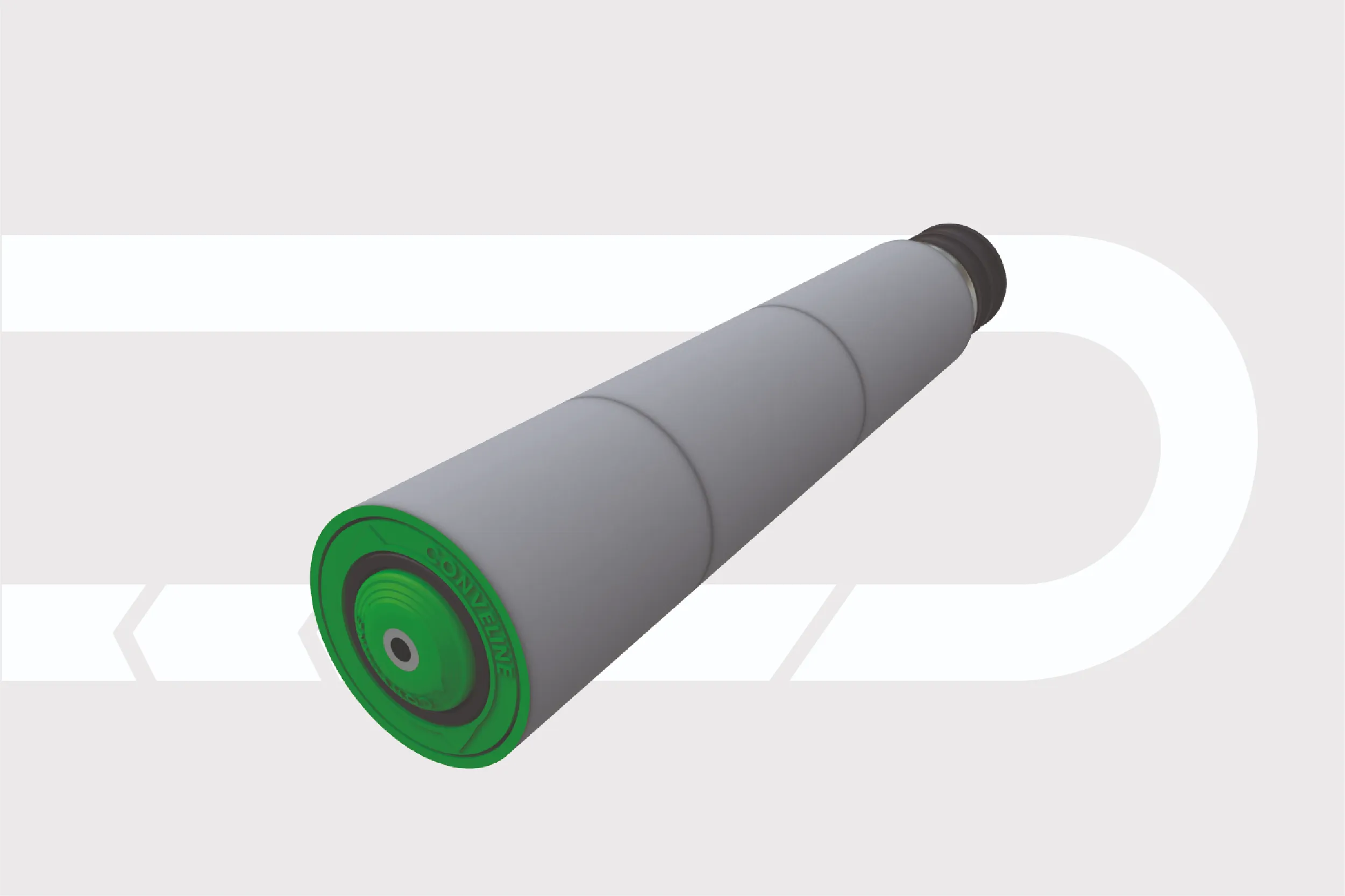

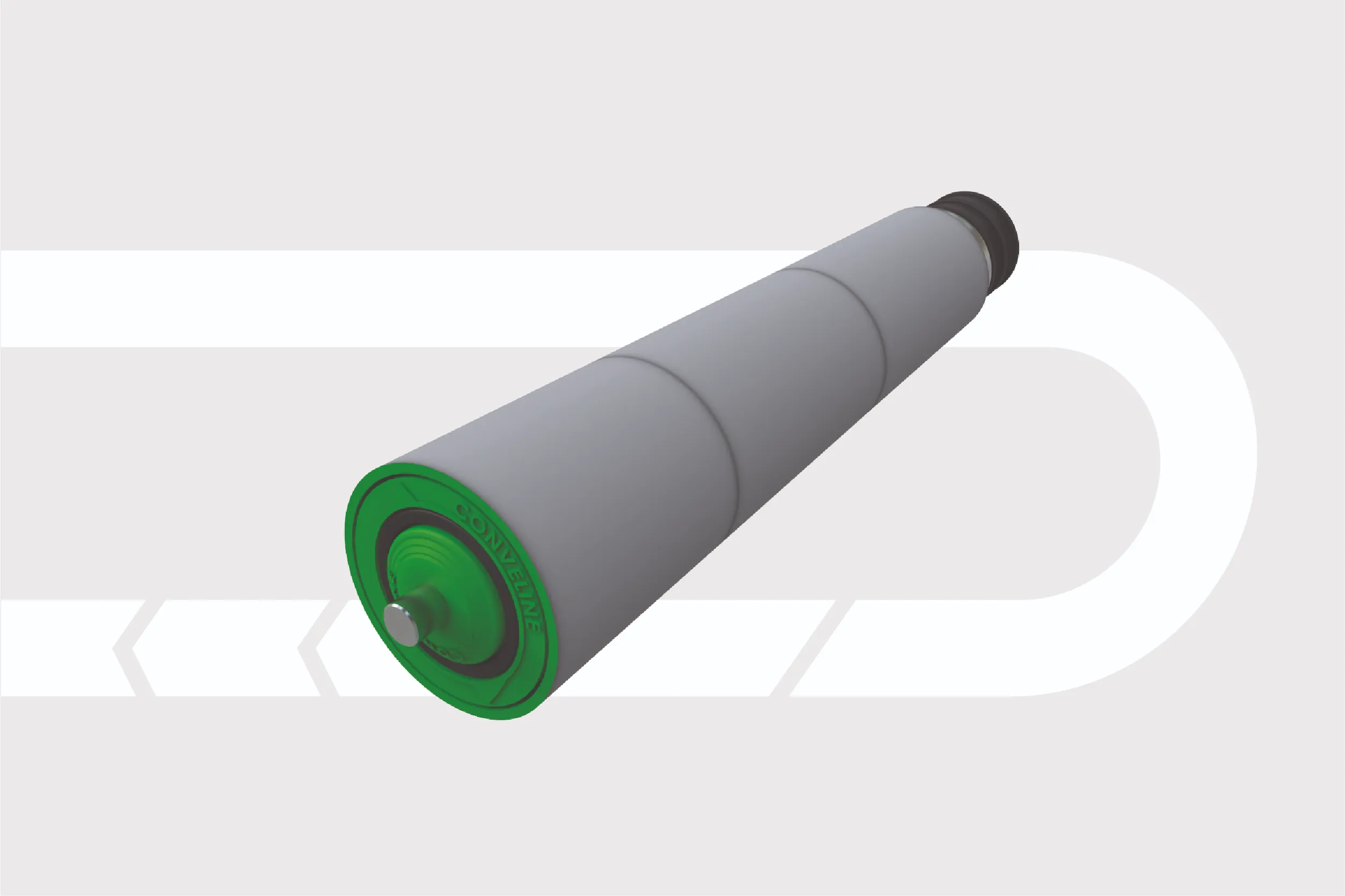

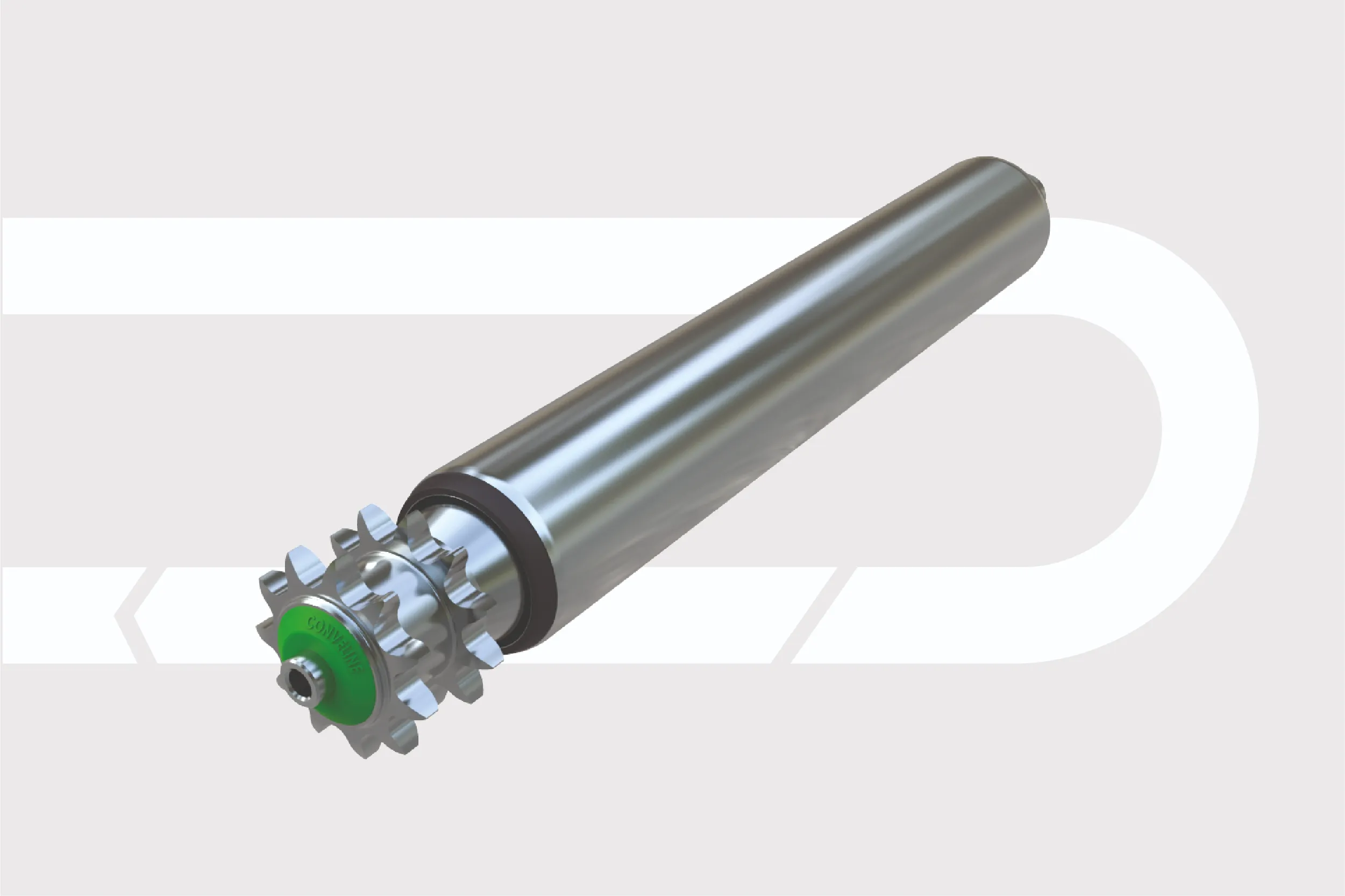

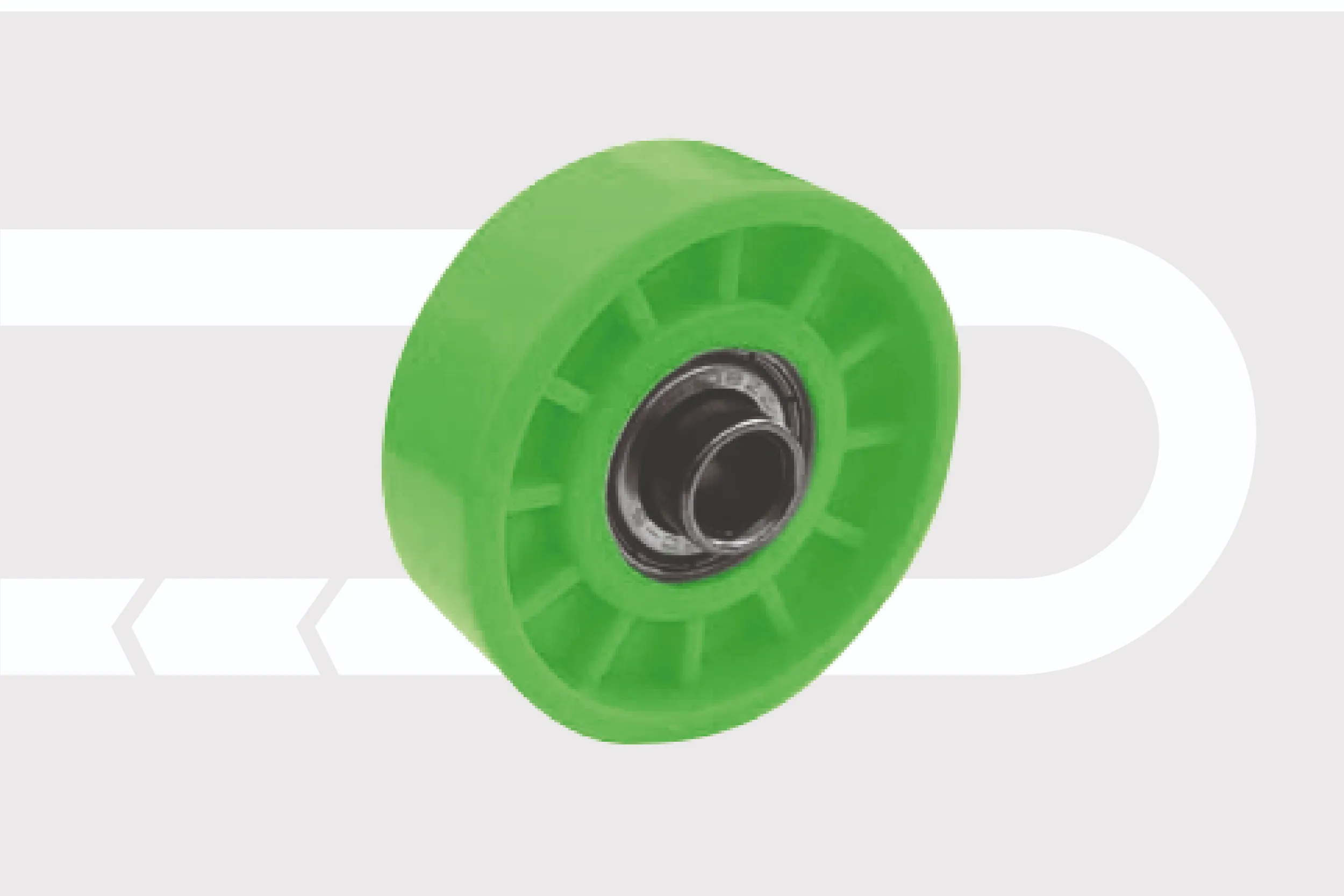

Our diverse range of rollers is particularly suitable for conveyors used in the food processing industry. These rollers facilitate the sorting and categorization of various items such as fruits, vegetables, empty bottles, crates, and more. Additionally, they enable the sorting of tablets and capsules by weight, ensuring quality control in the pharmaceutical industry. Moreover, our rollers are also employed in sorting waste in the recycling industry.

Automation and Precision

The sorting process is highly automated and precise, capable of reading barcodes, sizes, volumes, colors, and other criteria as per the specific requirements of customers. This advanced level of automation and precision ensures accurate sorting, enhancing operational efficiency.

Versatile Sorting Capabilities

Our sorting line incorporates various components that enable efficient sorting across multiple industries. These components include split conveyors, select conveyors, electronic weighing systems, camera checks, and product selection and delivery mechanisms. This comprehensive system caters to the needs of industries such as component manufacturing, machine parts, logistics, e-commerce, and agricultural product manufacturing, significantly boosting productivity.

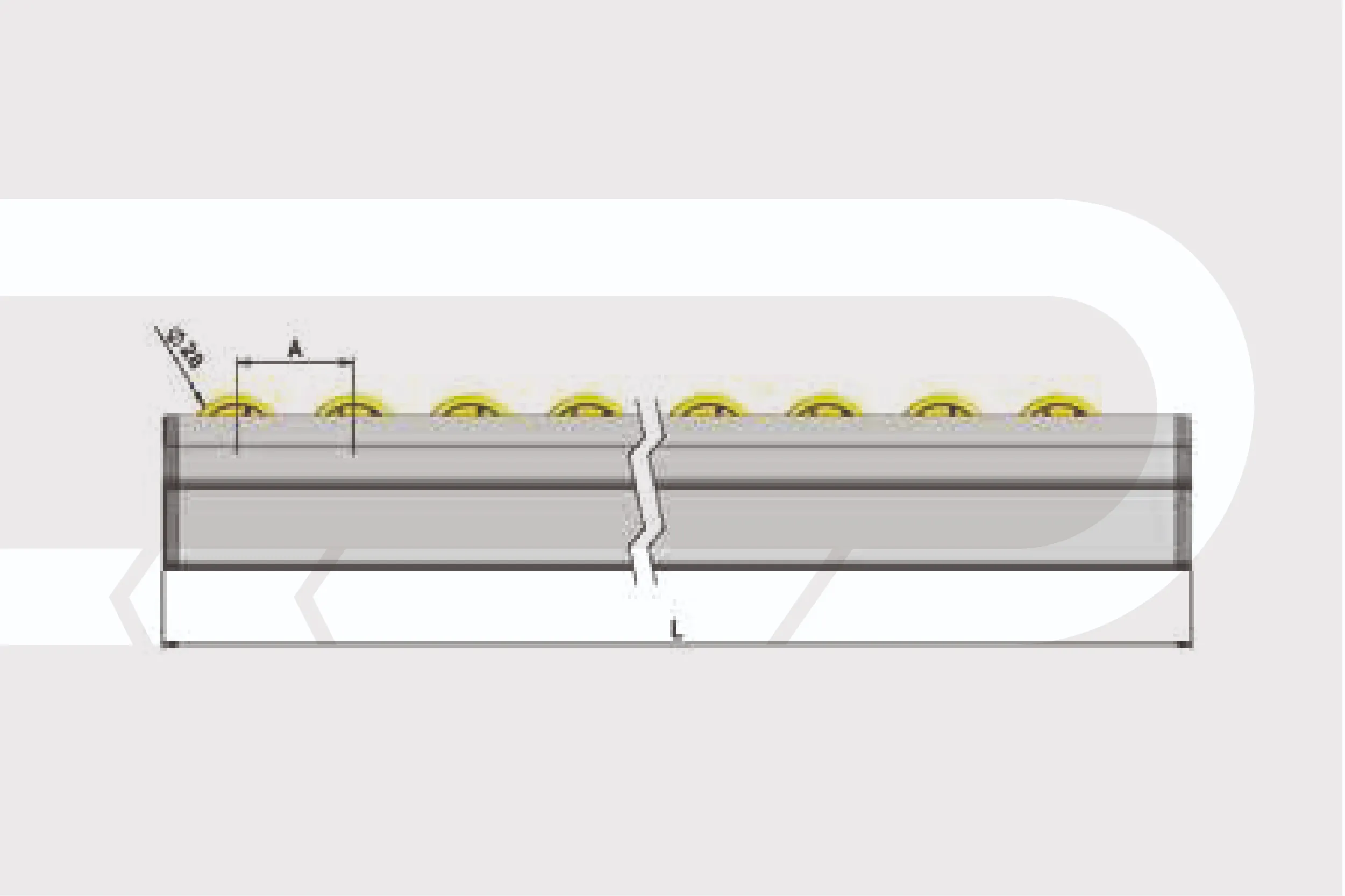

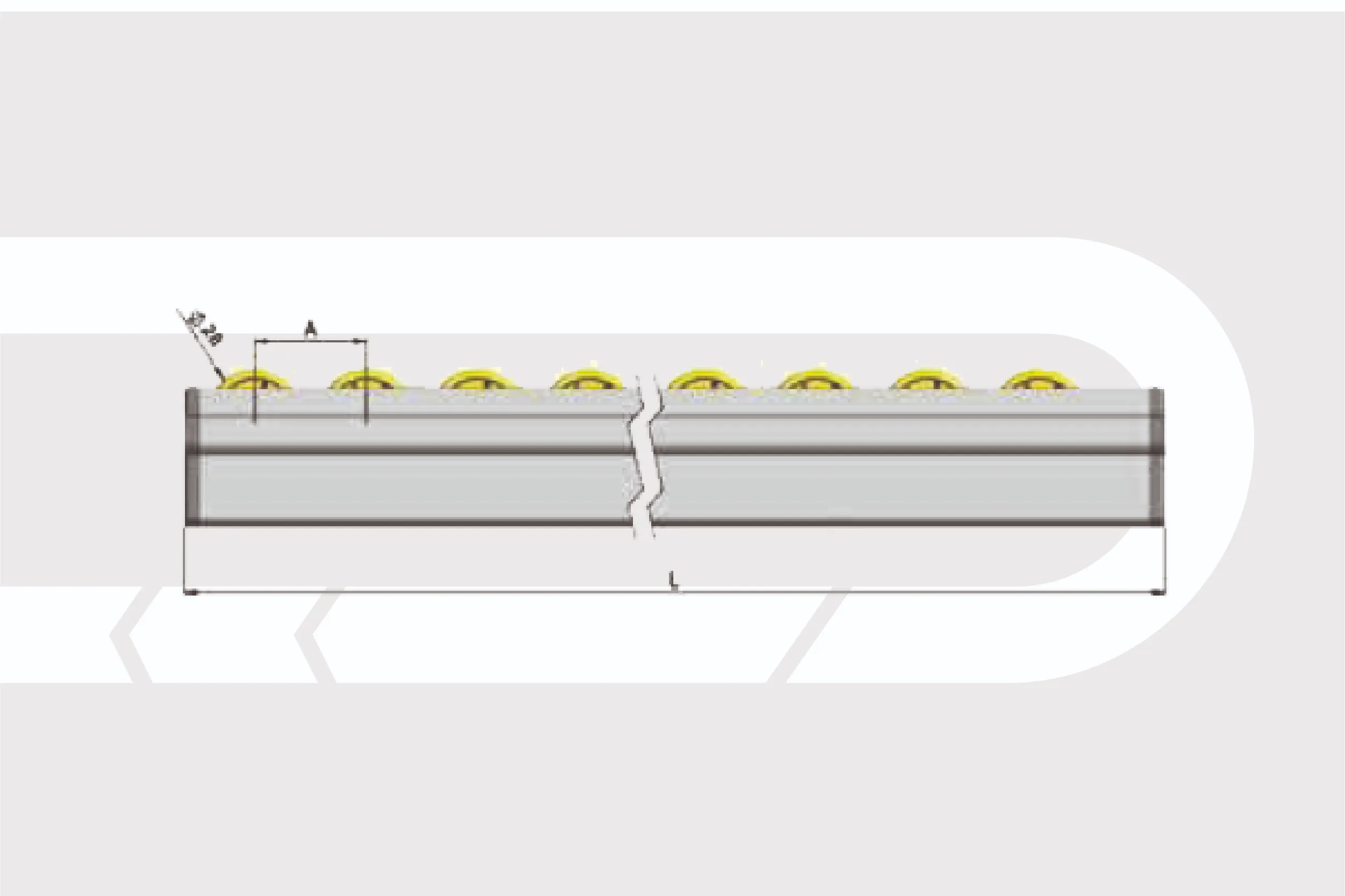

Factors Affecting Yield

Several factors impact the yield of the sorting process. The lengths and weights of the objects being sorted, the conveyor speed, and the required spacing between products all play a crucial role in achieving optimal sorting efficiency. Careful consideration of these factors ensures maximum yield and productivity