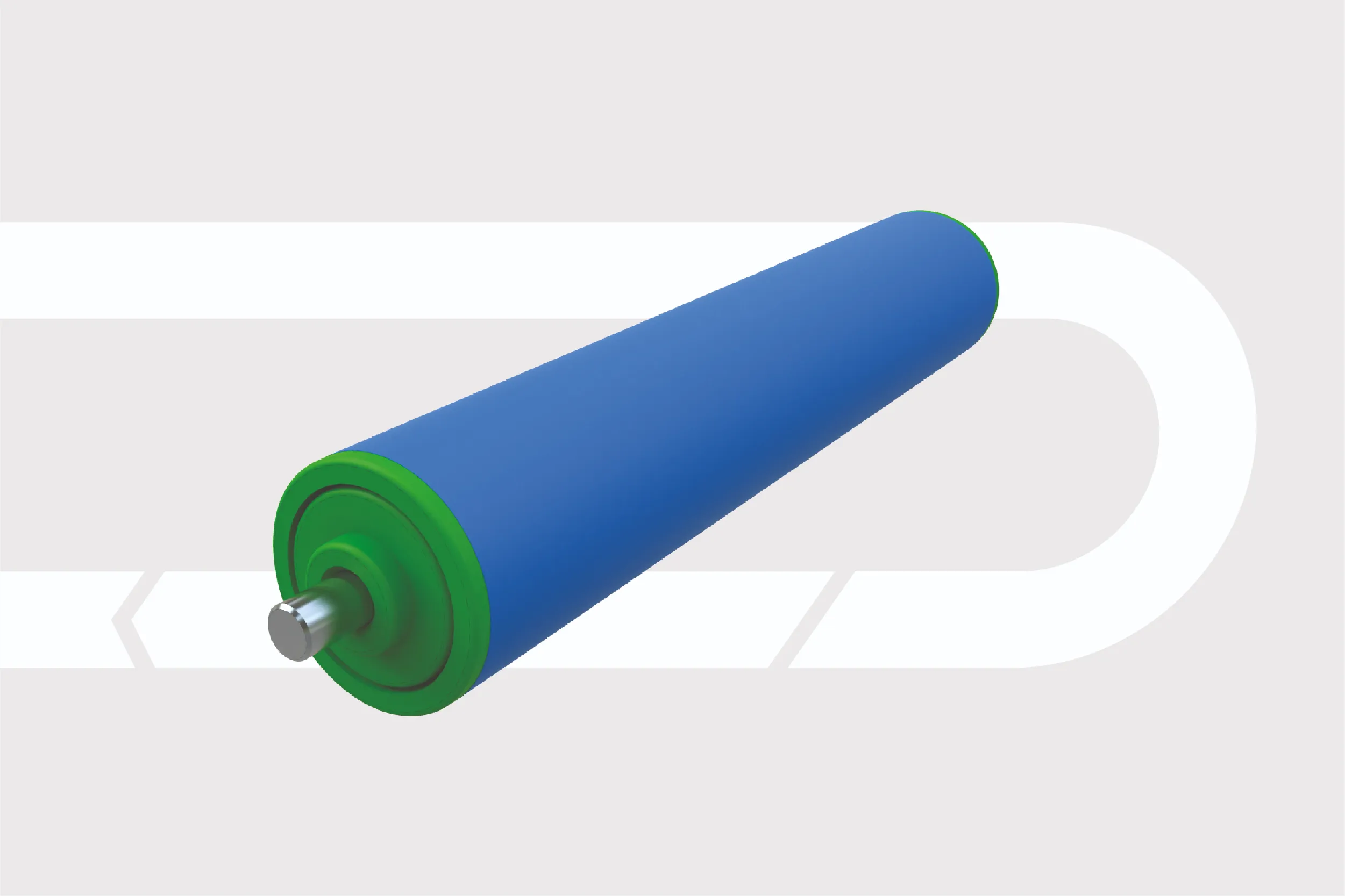

Gravity Conveyor Roller

Gravity conveyor rollers are a cost-effective and straightforward means of moving loads from one point to another.

Our extensive range of gravity rollers caters to applications from light to heavy duty. The free running bearings of our gravity rollers are particularly advantageous for gravity applications as they allow for the optimum performance of the rollers.

Additionally, we offer a diverse range of other gravity roller options that provide a handling performance of up to 500kg per roller.

At Conveline, we understand the importance of choosing the right gravity rollers for your specific application. That's why we offer a variety of sizes and designs to ensure that you get the most out of your conveyor system.

Our gravity rollers are manufactured using high-quality materials and engineered to meet the highest standards of performance and durability. Whether you need rollers for straight or curved conveyor systems, we have the expertise and experience to provide you with the right solution.

Specifications:

| Series | Product Features | Diameter Range | Shaft Range |

|---|---|---|---|

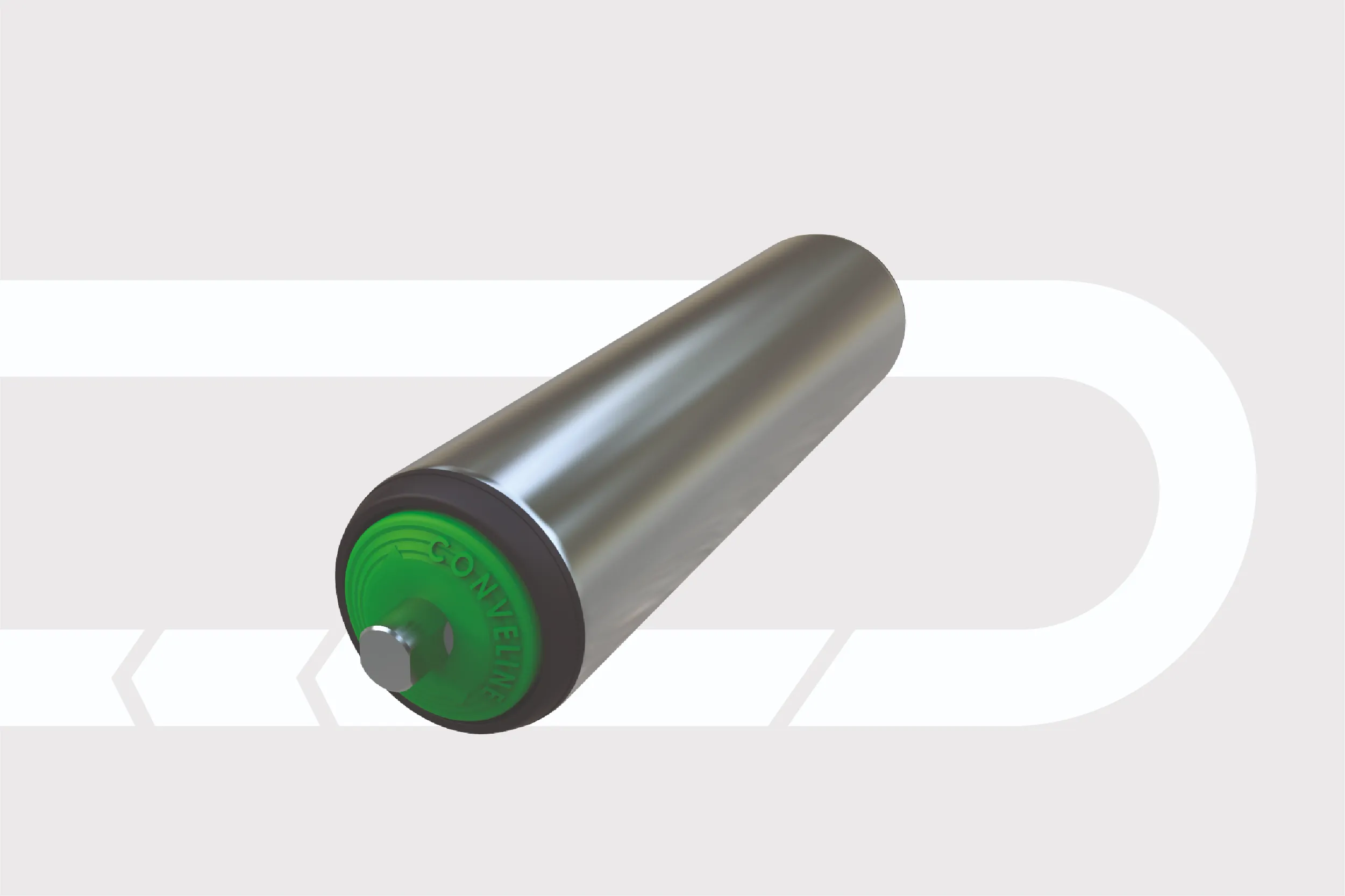

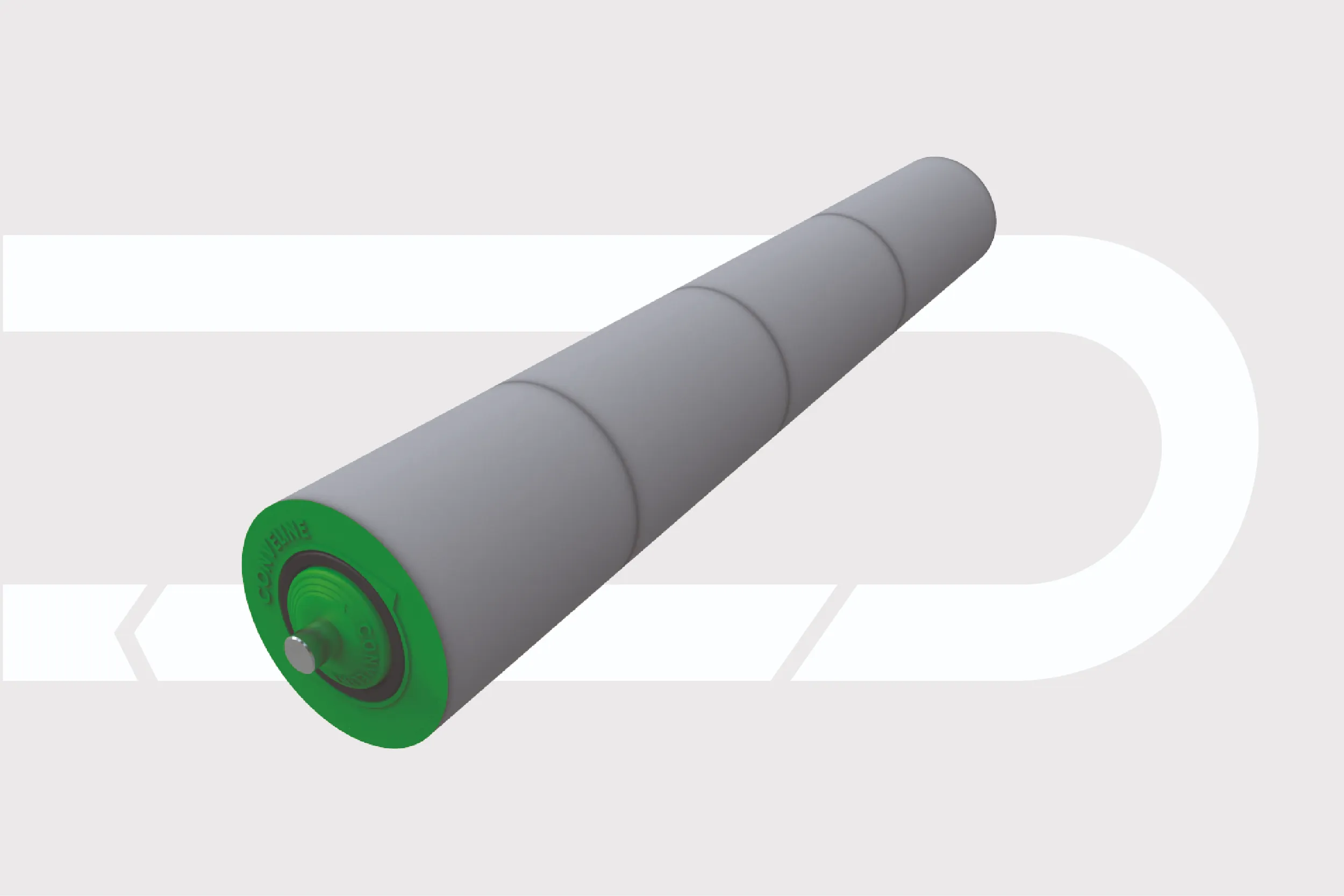

| 1101 | PVC tube, polyamide bearing housing, light duty conveyor rollers | 25, 38, 50 | 8,10,12 |

| 1102 | Light and medium duty universal conveyor rollers, polyamide bearing housing | 25, 38, 50, 60 , 76, 89 | 8,10,11,14,20 |

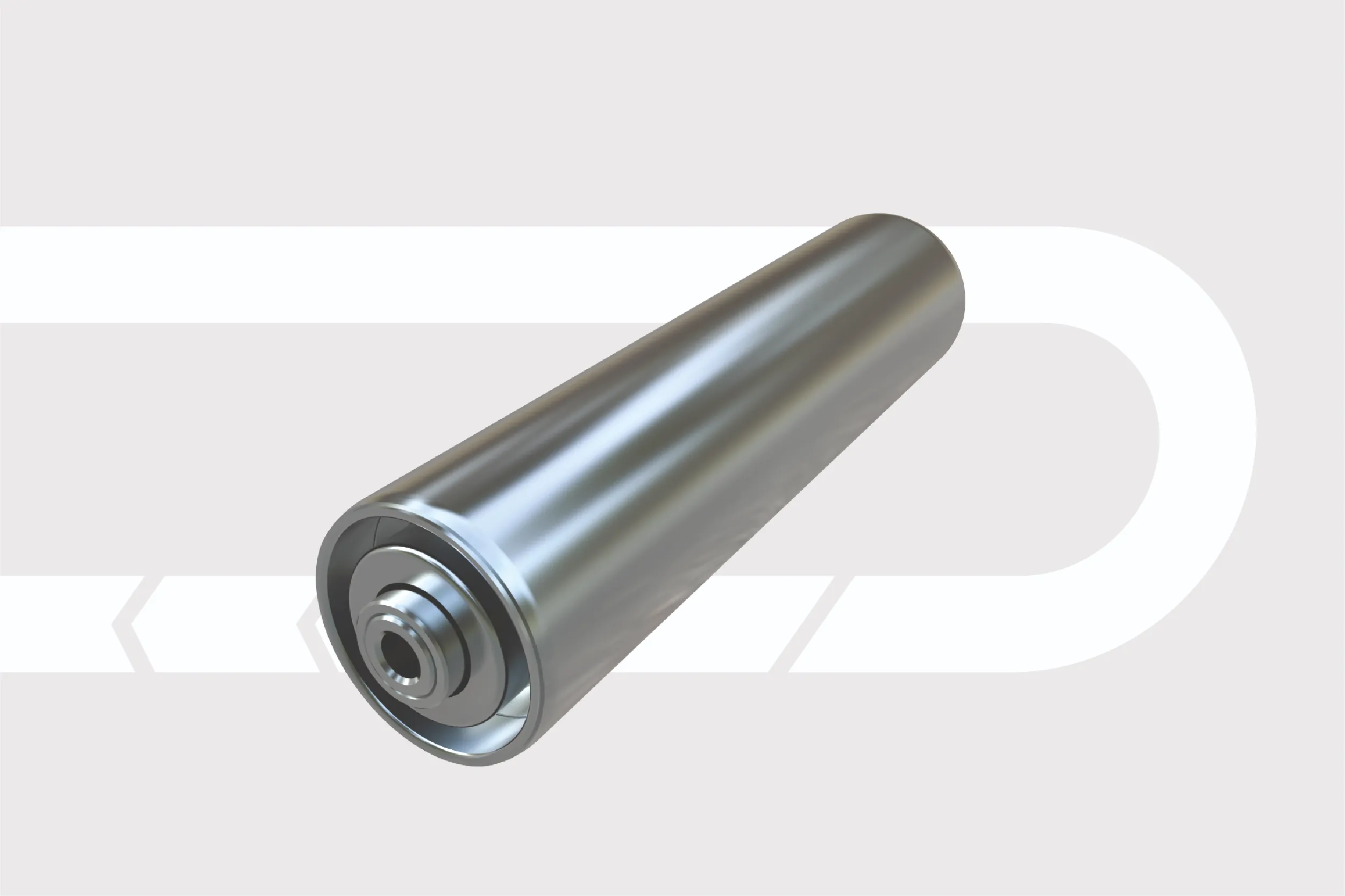

| 1103 | Gravity conveyor rollers, steel bearing housing | 50, 76, 89 | 14,20 |

Features and Options:

- Free running bearings

- Wide range of tube and shaft options

- Mild steel, stainless steel and plastic options

- Wide range to handle from 100gm to 500kg per roller capacity

- Our most economical price rollers

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Roller Range :

Usage of Gravity Rollers

Usage of Gravity Rollers

Gravity rollers are a commonly used type of conveyor roller that relies on the force of gravity to move items from one place to another. These rollers are often used in manufacturing and distribution facilities to move products along assembly lines or to transport them to storage areas.

One of the primary advantages of gravity rollers is their simplicity. Unlike other types of conveyor systems that rely on motors and belts to move items, gravity rollers require no external power source. This means they are easy to install, operate, and maintain, which can result in significant cost savings for businesses.

Gravity rollers are also versatile and can be customized to meet the specific needs of a variety of industries. They come in different sizes, lengths, and materials, allowing businesses to choose the roller that best fits their unique application. Additionally, some gravity rollers come equipped with features such as brakes or adjustable height, providing even greater flexibility in their use.

Frequently Asked Questions

Frequently Asked Questions

1. What are gravity rollers used for?

Gravity rollers are used for material handling in various industries such as manufacturing, distribution, and warehousing. They provide a low-cost, efficient way to move products and materials without the need for external power sources.

2. How do gravity rollers work?

Gravity rollers work on the principle of gravity. When products or materials are placed on the rollers, they move along the rollers' surface due to gravity's force. Gravity rollers do not require any external power source to operate.

3. What are the benefits of using gravity rollers?

Gravity rollers offer various benefits, including low cost, low maintenance, ease of use, and energy efficiency. They can also improve productivity by increasing the speed of material handling operations and reducing the need for manual labor.

4. Can gravity rollers be customized for specific applications ?

Yes, gravity rollers can be customized to meet specific application requirements. The rollers' size, spacing, and material can be customized to accommodate different product sizes and weights. The number of rollers and their positioning can also be adjusted to fit the layout of the material handling system.

We Export Gravity Rollers Worldwide

We Export Gravity Rollers Worldwide

Russia | USA | UAE | Australia | Malaysia | France | Kuwait | Saudi Arabia | Singapore | Switzerland | Qatar | South Korea | Bangladesh | Czech Republic | The Netherlands | Kazakhstan | Nigeria | Vietnam | Oman | Thailand | Mexico | Argentina | Brazil | Canada | India | Japan | Indonesia | New Zealand | Egypt | South Africa | Philippines | Turkey | Greece | Norway | Sweden | Portugal | Spain | Italy | Belgium | Poland | Ireland | Austria | Denmark | Finland | Israel | Iran | Iraq | Lebanon | Jordan | Syria | Libya | Algeria | Morocco | Sudan | Kenya | Uganda | Zimbabwe | Angola | Cambodia | Nepal | Sri Lanka | Myanmar | Afghanistan | Ethiopia | Ghana | Peru | Chile | Bolivia | Honduras | Guatemala | Ecuador | Paraguay | Uruguay | Serbia | Croatia | Bosnia and Herzegovina | Iceland | Luxembourg | Belarus | Ukraine | Lithuania | Latvia | Estonia | Georgia | Armenia | Azerbaijan | Yemen | Bahrain | Cyprus | Maldives | Brunei | Bhutan | Laos | Mauritius | Seychelles | Barbados | Jamaica | Trinidad and Tobago | Fiji | Solomon Islands | Micronesia | Vanuatu | Malta | Albania | Moldova | Slovenia | Macedonia | Montenegro | Kosovo | Suriname | Guyana | Belize | Nicaragua | El Salvador | Panama | Costa Rica | The Bahamas | Eswatini | Botswana | Namibia | Lesotho | Zambia | Malawi | Rwanda | Burundi | Djibouti | Eritrea | Somalia | Chad | Republic of the Congo | Democratic Republic of the Congo | Gabon | Equatorial Guinea | Guinea | Guinea-Bissau | The Gambia | Liberia | Sierra Leone | Togo | Benin | Burkina Faso | Ivory Coast | Senegal | Mali | Niger | Mauritania | Mozambique | Madagascar | Turkmenistan | Uzbekistan | Tajikistan | Kyrgyzstan | Palestine | East Timor | China | Pakistan | Hungary | Romania | Bulgaria | Slovakia | Venezuela | Colombia