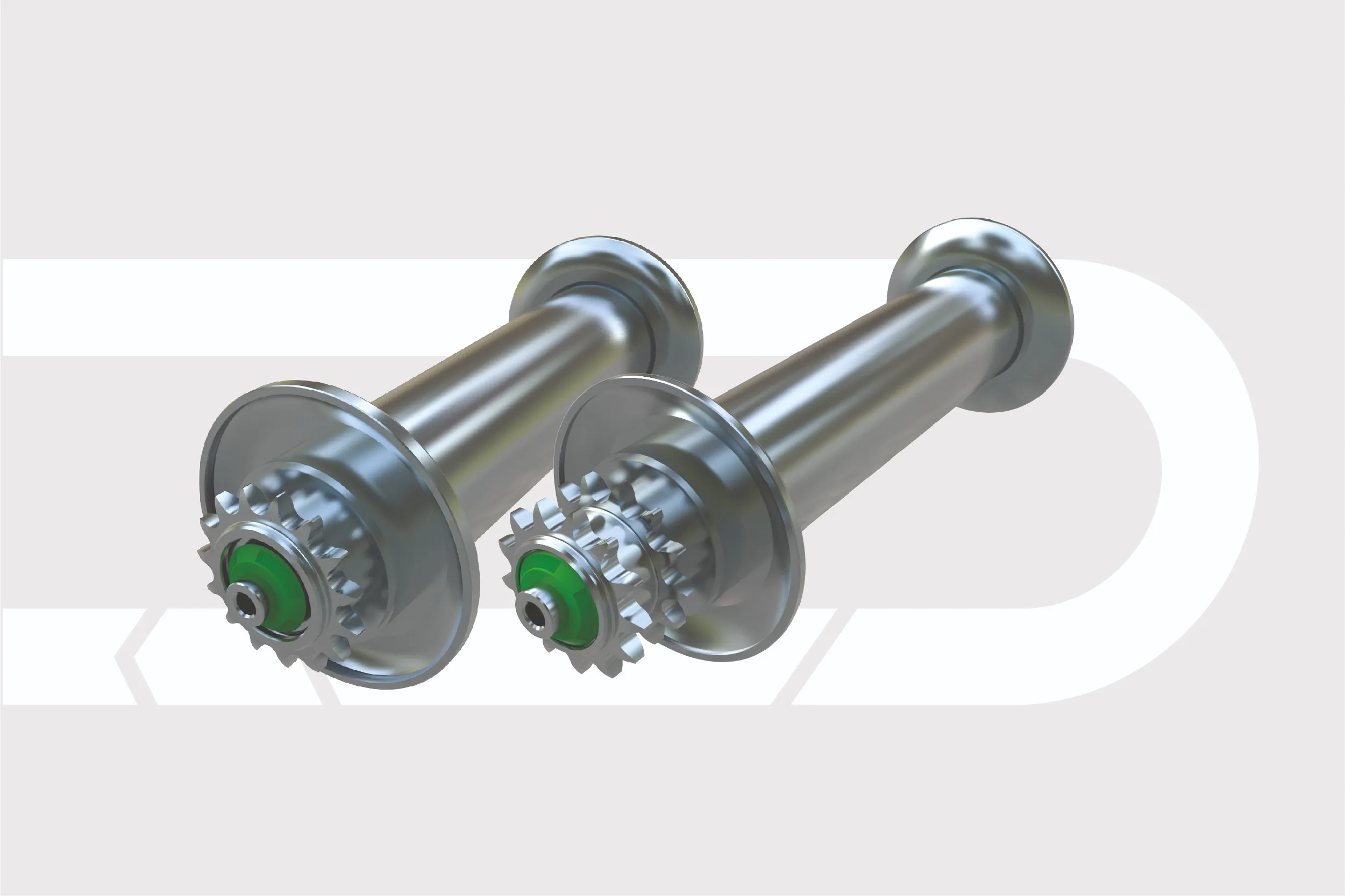

Fixed Driven Conveyor Rollers

Fixed Driven Conveyor rollers offer the most economical and simplest powered method form of transporting loads from the one point to another point.

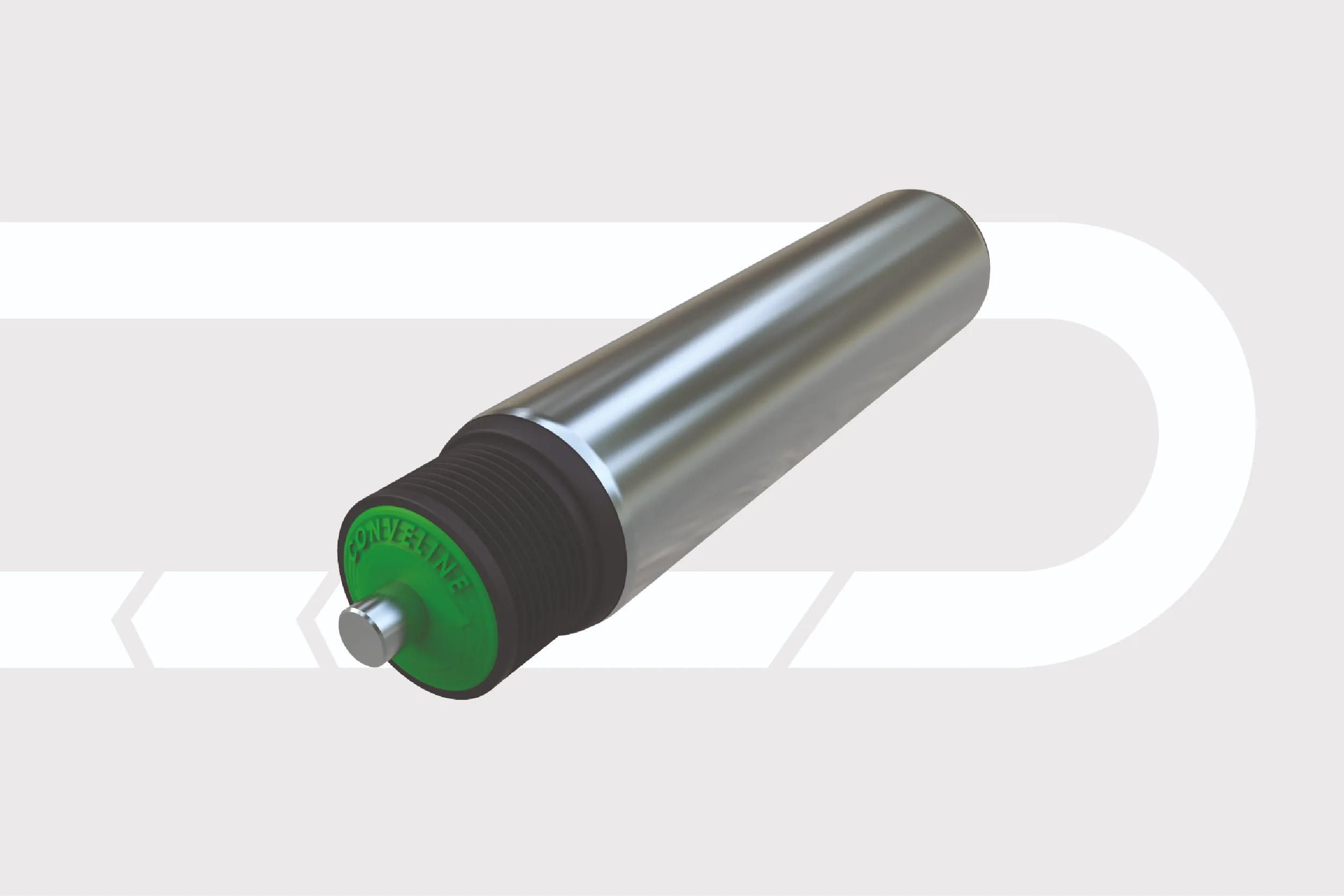

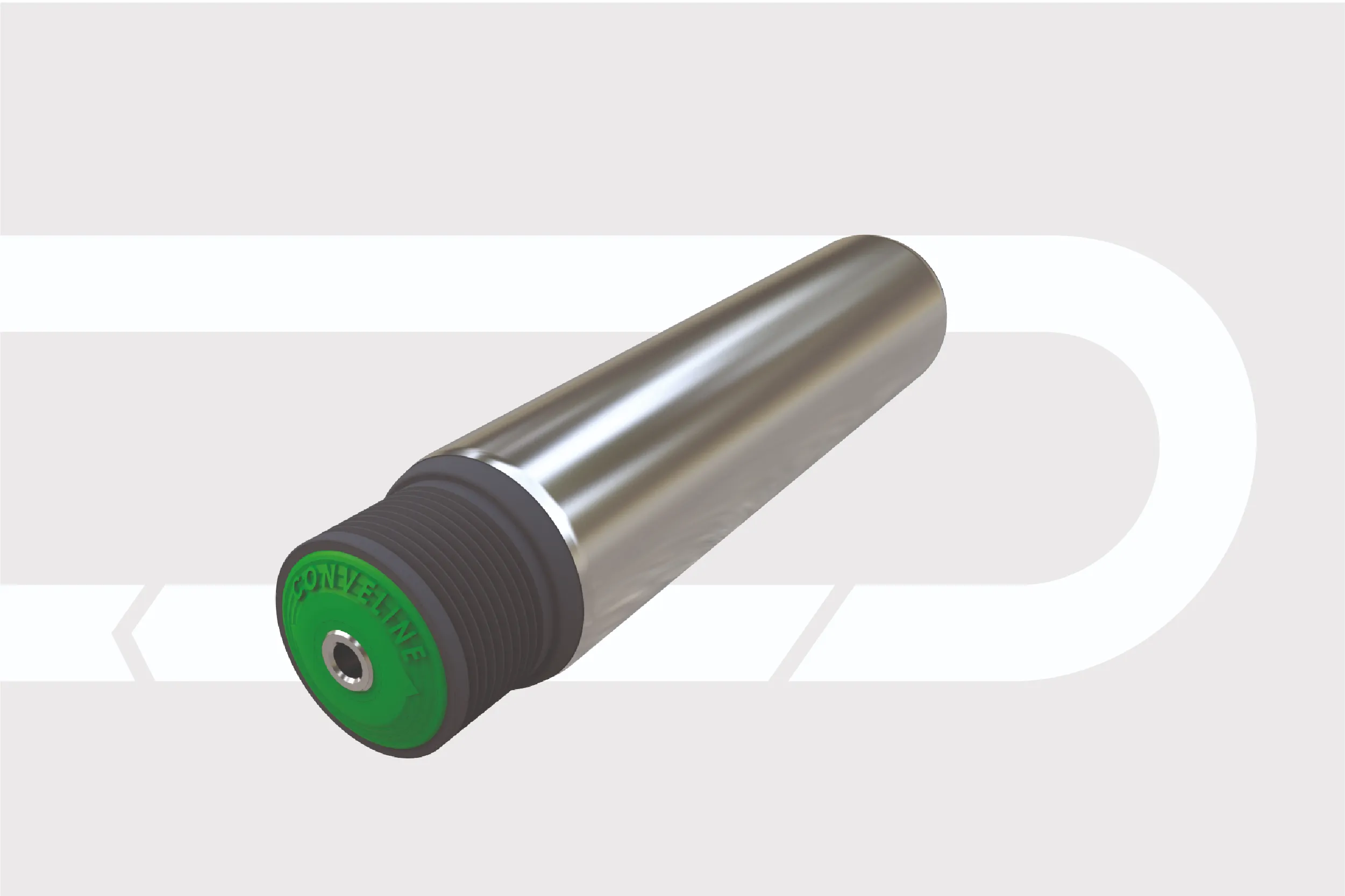

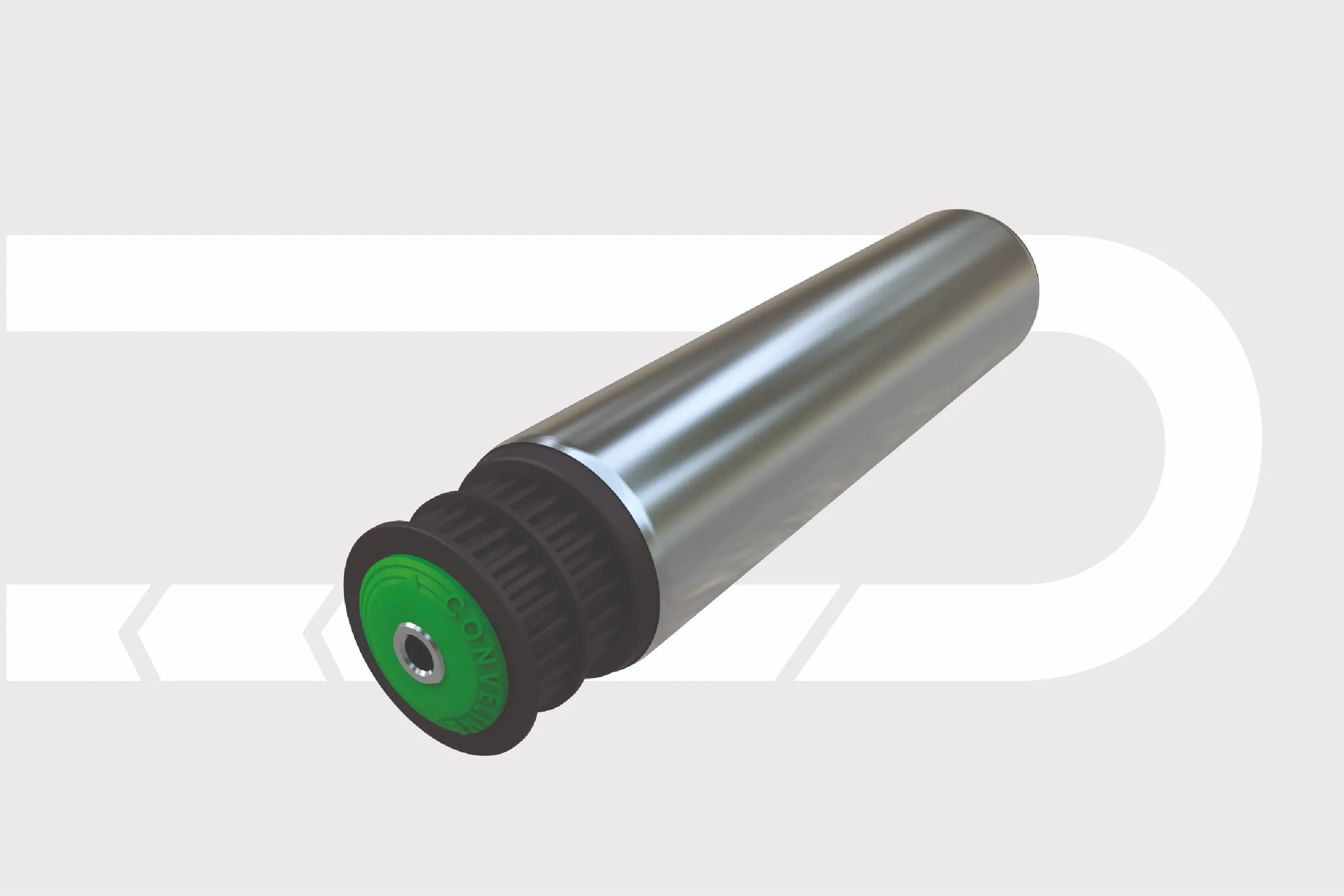

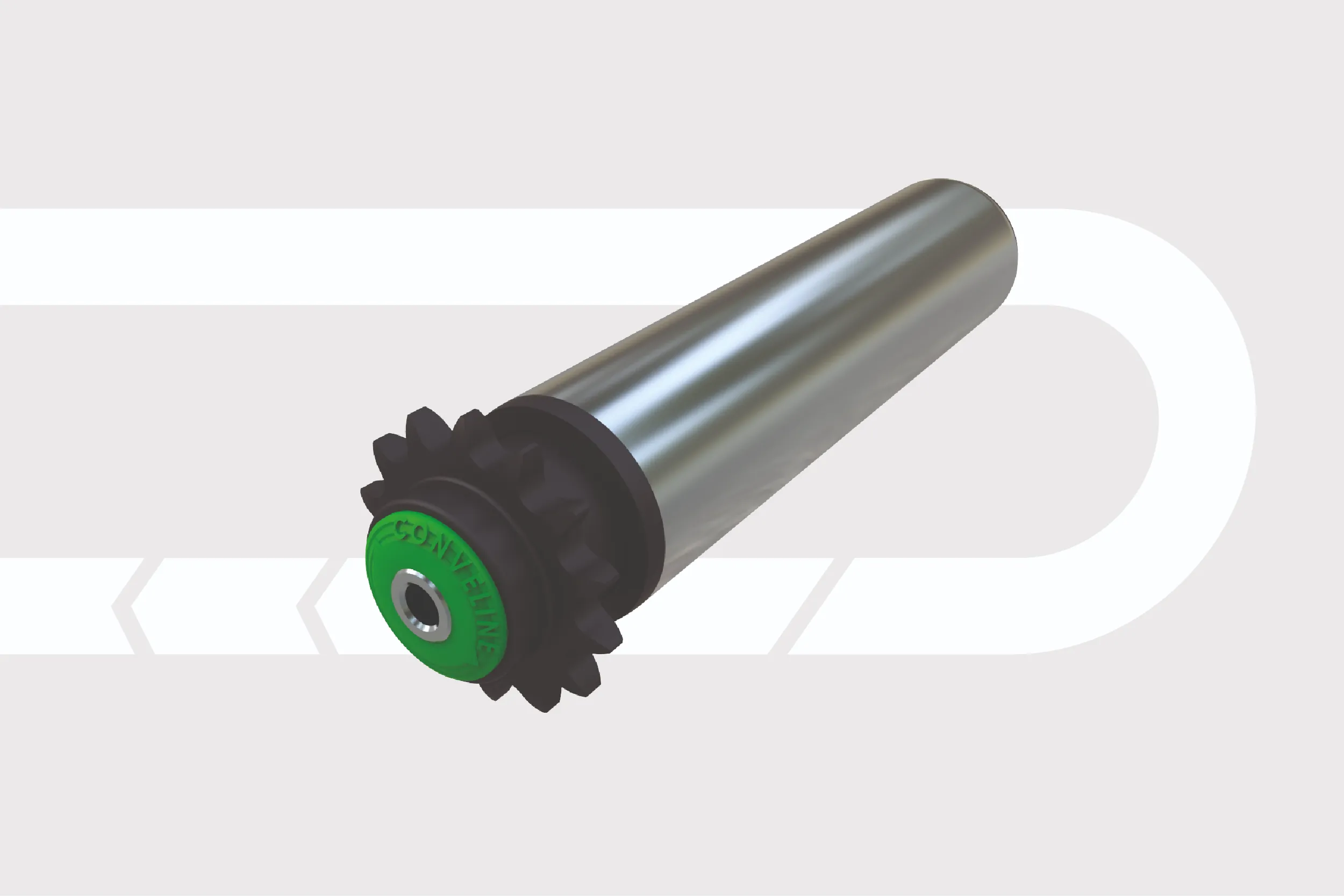

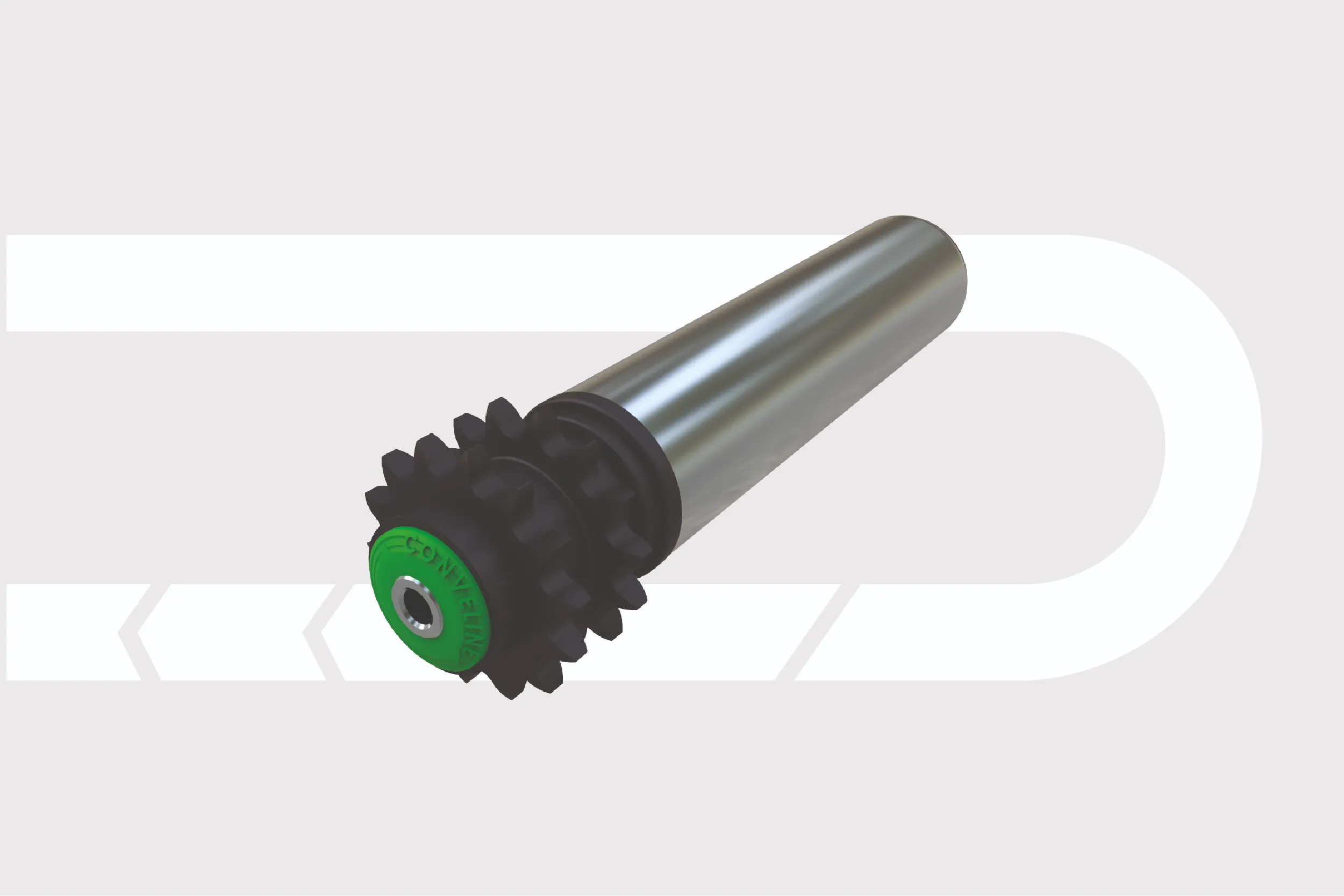

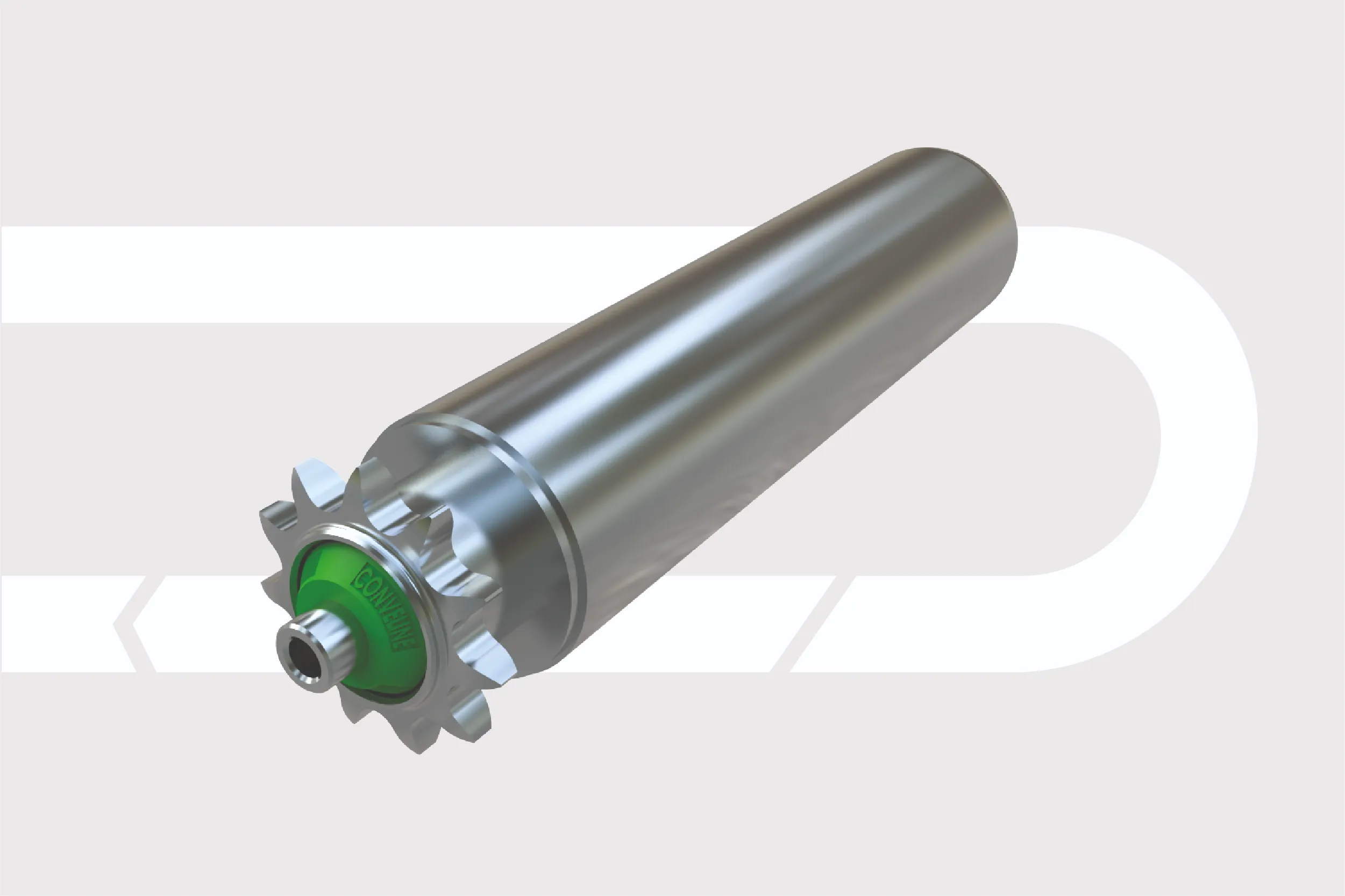

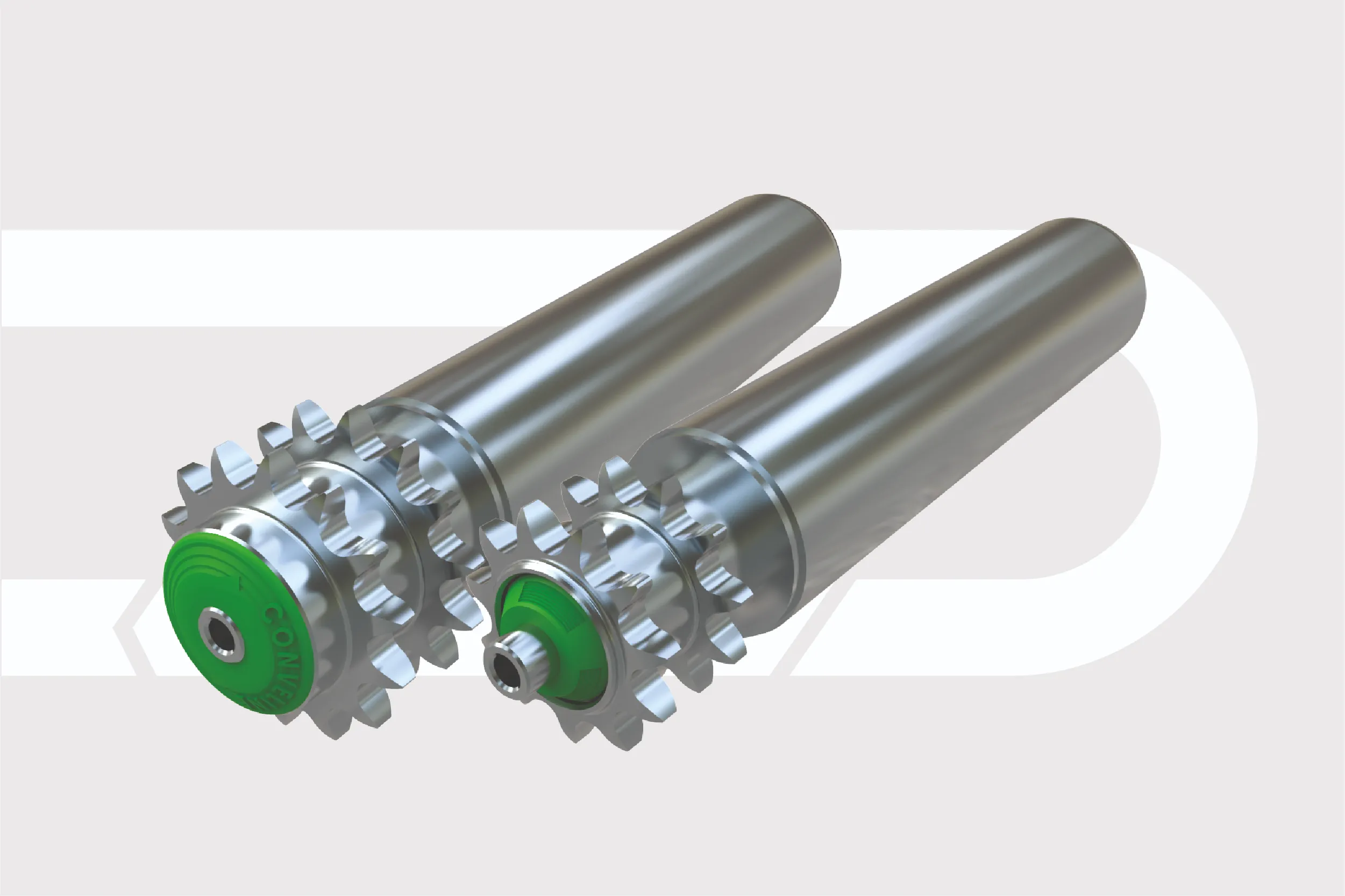

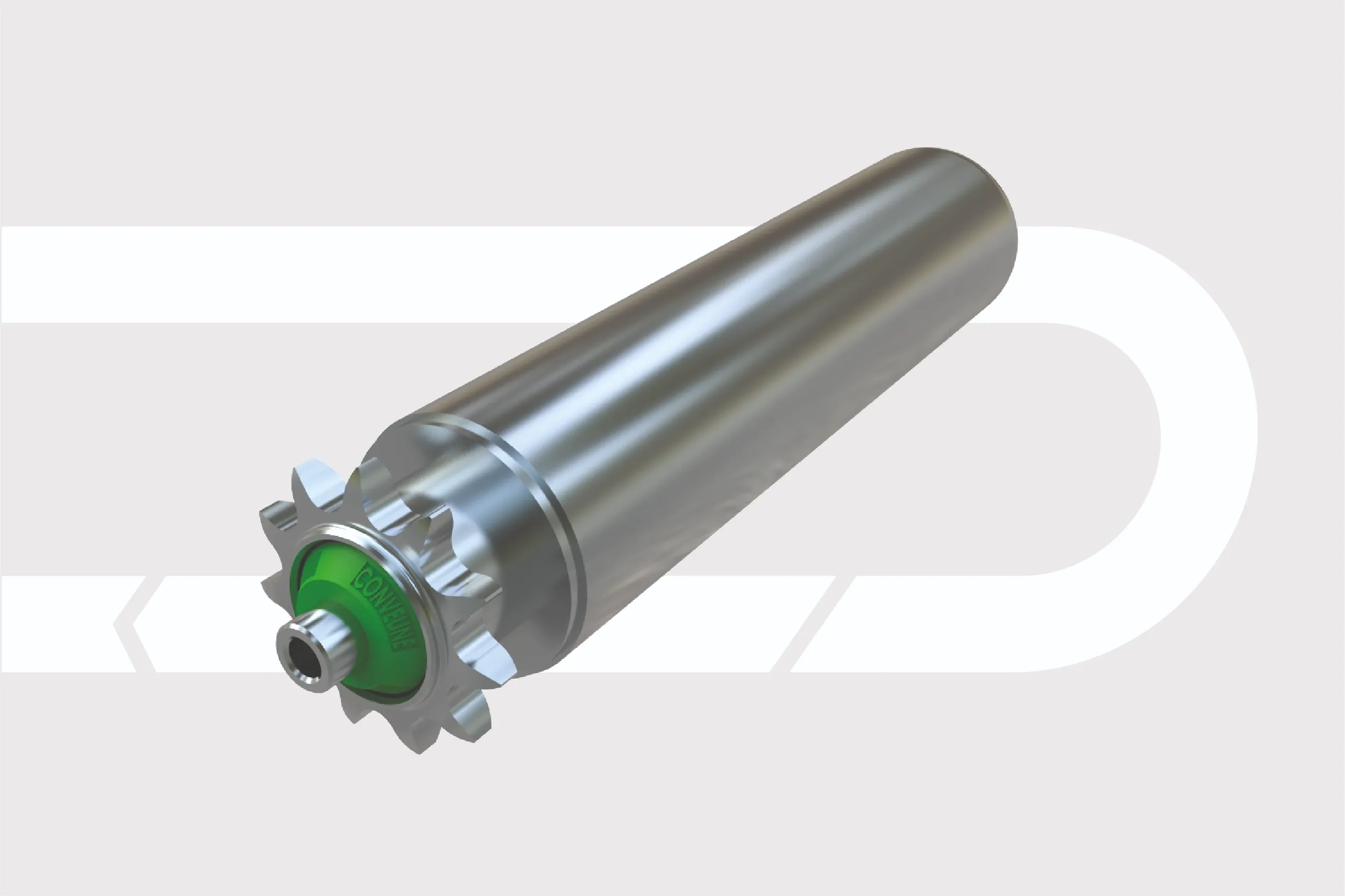

Our wide range of Driven rollers covers applications from light to heavy duty. Driven rollers are ideally suited or can be supplied with Single sprocket, Double sprocket, O ring, Poly V belt and timing belt drive rollers. Rollers from 50mm diameter to 89mm diameter option.

Belt Driven is suited for reliable, low noise, low environmental pollution, able to run high speed.

Chain Driven is suited for high load capacity and medium load capacity, wide range of working environments including oil, water and high temperature and up to 30m/min speed.

Specifications:

| Series | Product Features | Diameter Range | Shaft Range |

|---|---|---|---|

| 1201 / 1202 | O belt rollers, single or double groove light/medium duty conveyor rollers, custom made groove | 50 | 11, 14 |

| 1203 | O belt pulley rollers, light/medium duty conveyor rollers | 50 | 11, 14 |

| 1204 | Poly V belt pulley rollers, medium duty and high speed conveyor rollers | 50 | 11, 14 |

| 1205 | Timing belt pulley rollers, medium duty and high speed conveyor rollers | 50 | 11, 14 |

| 1206 / 1207 | Polymer sprocket rollers, single or double sprocket, medium duty and low running noise, polyamide bearing housing | 50 | 14 |

| 1208 / 1209 | Steel sprocket, single or double sprocket, medium/heavy duty conveying application, polyamide bearing housing | 50, 60, 76, 89 | 14, 15, 20 |

| 1210 / 1211 | Steel sprocket, steel bearing housing, heavy duty conveying, strong and reliable | 50, 76, 89 | 14,15, 20 |

Features and Options:

- Free running bearings

- Wide range of tube and shaft options

- Mild steel, stainless steel and plastic options

- Wide range to handle from 100gm to 500kg per roller capacity

- Our most economical price rollers

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Roller Range :

Usage of Fixed Driven Rollers

Usage of Fixed Driven Rollers

Fixed driven rollers are an essential component in many conveyor systems, providing power to move materials along a designated path. These rollers are driven by a motor or another power source, which rotates the roller to move the material. Fixed driven rollers are commonly used in production and manufacturing facilities, as well as in airports and shipping centers.

One of the primary advantages of fixed driven rollers is their ability to move heavy loads with ease. They are also incredibly efficient and reliable, requiring minimal maintenance and upkeep. The rollers are made from durable materials, such as steel or aluminum, which can withstand wear and tear over time.

Fixed driven rollers can be used in various types of conveyor systems, including gravity conveyors, powered roller conveyors, and belt conveyors. They come in a range of sizes and designs to fit the specific needs of each application.

In summary, fixed driven rollers are an essential component of conveyor systems used in industries such as manufacturing, production, and transportation. They are efficient, durable, and can move heavy loads with ease, making them a popular choice for many businesses.

Frequently Asked Questions

Frequently Asked Questions

1. What is a fixed driven roller?

A fixed driven roller is a type of conveyor roller that is driven by a motor or power source and is fixed in place. It is used to move materials or products along a conveyor belt.

2. What are the benefits of using fixed driven rollers?

Using fixed driven rollers can provide better control and precision in moving materials or products, as they are powered and fixed in place. They also have a higher load capacity compared to gravity rollers, making them ideal for heavy-duty applications.

3. Can fixed driven rollers be customized for specific applications?

Yes, fixed driven rollers can be customized according to the specific needs and requirements of an application. This includes the diameter, length, material, and other features such as bearings or coatings.

4. What are some common applications of fixed driven rollers?

Fixed driven rollers are commonly used in industries such as manufacturing, food and beverage, automotive, and logistics. They are used for moving materials or products along production lines, assembly lines, and packaging lines. They can also be used in transportation systems such as airports and warehouses.

We Export Fixed Driven Rollers Worldwide

We Export Fixed Driven Rollers Worldwide

Russia | USA | UAE | Australia | Malaysia | France | Kuwait | Saudi Arabia | Singapore | Switzerland | Qatar | South Korea | Bangladesh | Czech Republic | The Netherlands | Kazakhstan | Nigeria | Vietnam | Oman | Thailand | Mexico | Argentina | Brazil | Canada | India | Japan | Indonesia | New Zealand | Egypt | South Africa | Philippines | Turkey | Greece | Norway | Sweden | Portugal | Spain | Italy | Belgium | Poland | Ireland | Austria | Denmark | Finland | Israel | Iran | Iraq | Lebanon | Jordan | Syria | Libya | Algeria | Morocco | Sudan | Kenya | Uganda | Zimbabwe | Angola | Cambodia | Nepal | Sri Lanka | Myanmar | Afghanistan | Ethiopia | Ghana | Peru | Chile | Bolivia | Honduras | Guatemala | Ecuador | Paraguay | Uruguay | Serbia | Croatia | Bosnia and Herzegovina | Iceland | Luxembourg | Belarus | Ukraine | Lithuania | Latvia | Estonia | Georgia | Armenia | Azerbaijan | Yemen | Bahrain | Cyprus | Maldives | Brunei | Bhutan | Laos | Mauritius | Seychelles | Barbados | Jamaica | Trinidad and Tobago | Fiji | Solomon Islands | Micronesia | Vanuatu | Malta | Albania | Moldova | Slovenia | Macedonia | Montenegro | Kosovo | Suriname | Guyana | Belize | Nicaragua | El Salvador | Panama | Costa Rica | The Bahamas | Eswatini | Botswana | Namibia | Lesotho | Zambia | Malawi | Rwanda | Burundi | Djibouti | Eritrea | Somalia | Chad | Republic of the Congo | Democratic Republic of the Congo | Gabon | Equatorial Guinea | Guinea | Guinea-Bissau | The Gambia | Liberia | Sierra Leone | Togo | Benin | Burkina Faso | Ivory Coast | Senegal | Mali | Niger | Mauritania | Mozambique | Madagascar | Turkmenistan | Uzbekistan | Tajikistan | Kyrgyzstan | Palestine | East Timor | China | Pakistan | Hungary | Romania | Bulgaria | Slovakia | Venezuela | Colombia