Ball Transfer Unit Manufacturer

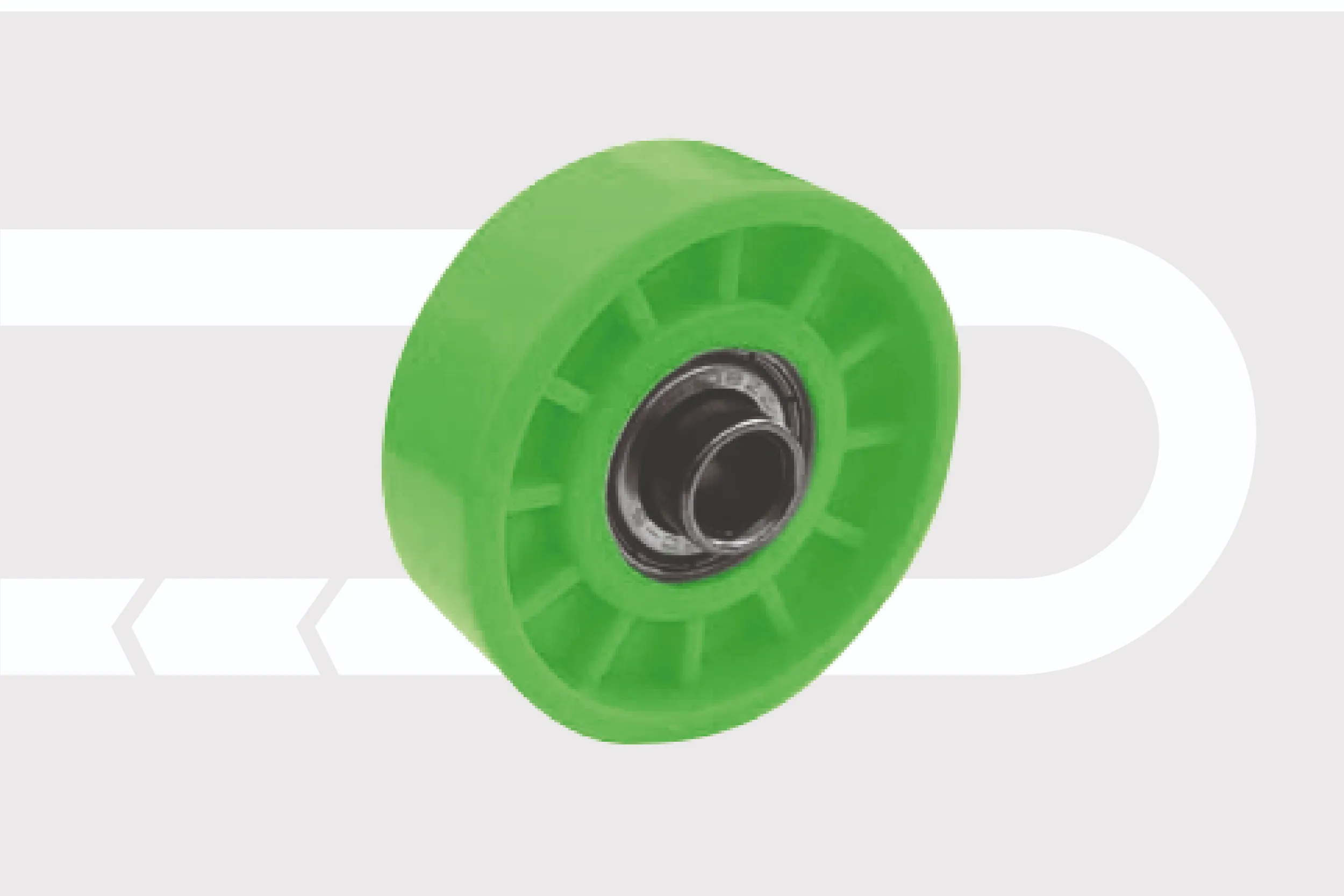

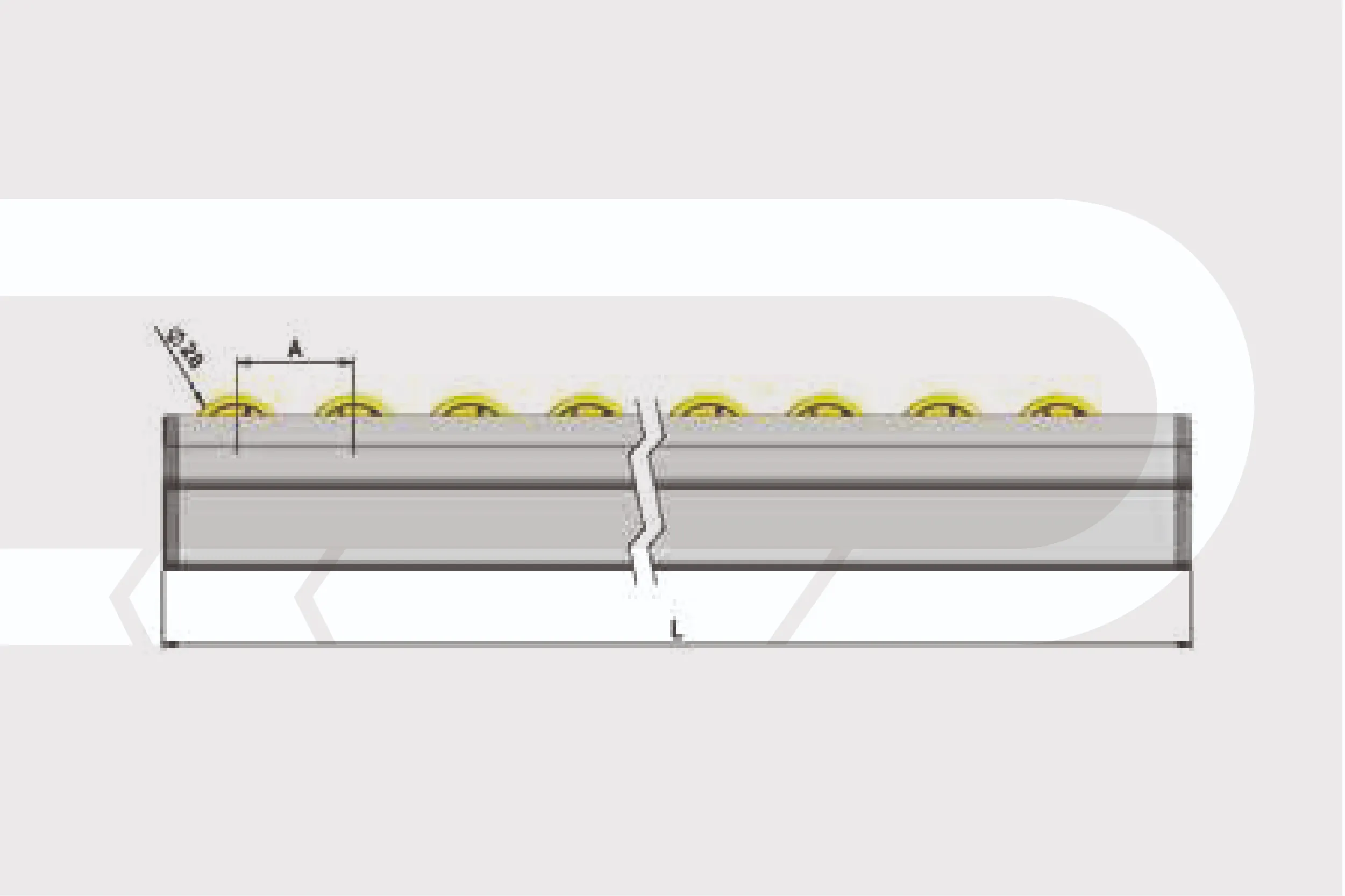

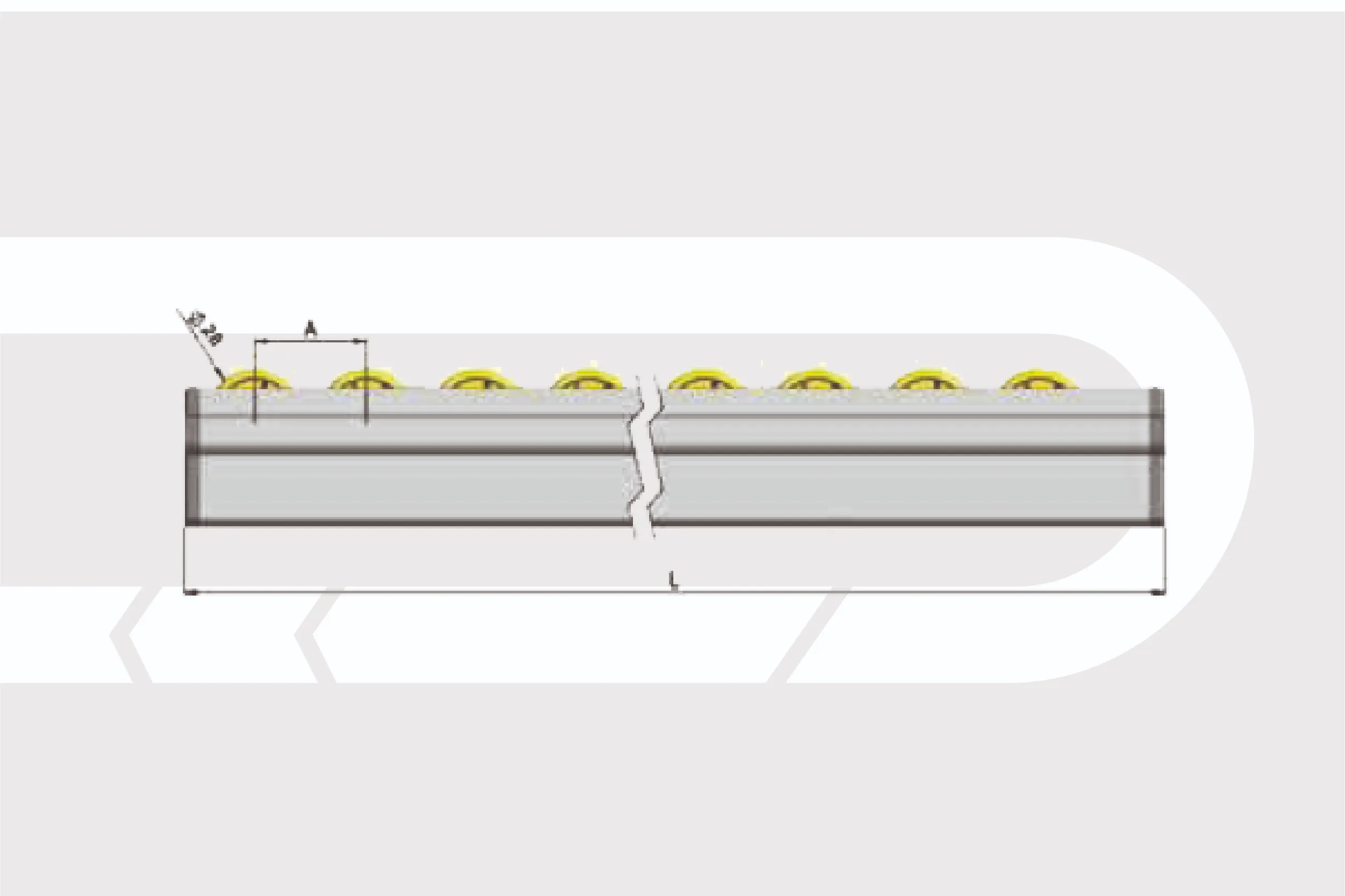

Conveline Rollers is a leading ball transfer unit manufacturer and supplier offering premium-quality solutions for smooth and efficient material handling. Our CA-01-B ball transfer units in India are designed to provide seamless multidirectional movement, ideal for conveyor systems, packaging units, assembly lines, and logistics operations. Engineered for strength and durability, these units support both static and dynamic loads of up to 40 kg and weigh just 126 gm. They are available in a variety of materials, including carbon steel, stainless steel, and nylon, with zinc-plated steel bodies for long-lasting performance.

Conveline Rollers, a reputable ball transfer unit manufacturer in India, provides reliable and high-performance units in a variety of sizes and specifications to fulfill a wide range of industrial needs. With a commitment to quality, innovation, and customer satisfaction, we continue to be the preferred choice for ball transfer units in India, helping businesses optimize their workflow and material movement.

Features and Options:

- Body and surface - steel, zine plated

- Static load - 40 kg / 88 lbs

- Dynamic load - 40 kg / 110 lbs

- Weight (gm) - 126

Usage of Ball Transfer Unit

Here are some of the key applications of Ball Transfer Units:

- Material Handling Systems: Widely used in conveyor tables for smooth and multidirectional movement of packages, sheets, and pallets.

- Assembly Lines: Enable easy positioning and rotation of heavy components during assembly processes.

- Airport Baggage Handling: Installed in baggage claim and sorting areas for effortless transfer and redirection of luggage.

- Logistics & Distribution Centers: Used in sorting and packaging lines to streamline the flow of parcels and goods.

- Pushcarts and Trolleys: Integrated into the base of carts and trolleys to allow easy mobility in all directions.

- Packaging Machinery: Enhance operational efficiency by enabling smooth transition of items between different stages.

- Furniture Applications: Installed in office chairs, cabinets, and household furniture for 360-degree movement and repositioning.

- Automated Systems: Essential in robotics and automation for moving parts or assemblies in tight or complex layouts.

- Workstations & Inspection Tables: Used for rotating or redirecting parts without manual lifting, reducing labor and improving ergonomics.

- Conveline Rollers’ Solutions: Offers high-quality, precision-engineered ball transfer units suitable for heavy-duty and light-duty applications across industries.

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Accessories Range :

Frequently Asked Questions

Frequently Asked Questions

1. What is a Ball Transfer Unit?

A ball transfer unit is a device that allows objects to move smoothly in any direction. It consists of a large ball supported by smaller ball bearings housed in a casing.

2. Where are Ball Transfer Units used?

They are used in conveyor systems, assembly lines, packaging machinery, airport baggage systems, trolleys, and furniture for multi-directional movement.

3. How does a Ball Transfer Unit work?

The main load-bearing ball rotates on a bed of smaller bearings, allowing free 360-degree movement with minimal effort.

4. What materials are Ball Transfer Units made from?

Common materials include stainless steel, carbon steel, and nylon depending on the load capacity and application environment.

5. Can Ball Transfer Units handle heavy loads?

Yes, industrial-grade units can handle loads ranging from a few kilograms to several hundred kilograms per unit.

6. Are Ball Transfer Units suitable for outdoor use?

Stainless steel or corrosion-resistant models can be used in outdoor or moist environments.

7. Can they be mounted in any direction?

Typically, they are mounted face-up but some special types allow inverted or side mounting based on application needs.

8. Do they require maintenance?

Minimal maintenance is needed, but regular cleaning and occasional lubrication improve lifespan and performance.

9. What size Ball Transfer Unit should I choose?

Size depends on the weight, shape, and dimensions of the item being transferred. Multiple units are often used together for balance.

10. Does Conveline Rollers manufacture custom Ball Transfer Units?

Yes, Conveline Rollers offers customizable options based on load capacity, material, and application requirements.