CA-01-F - Gravity Flow Rack Manufacturer

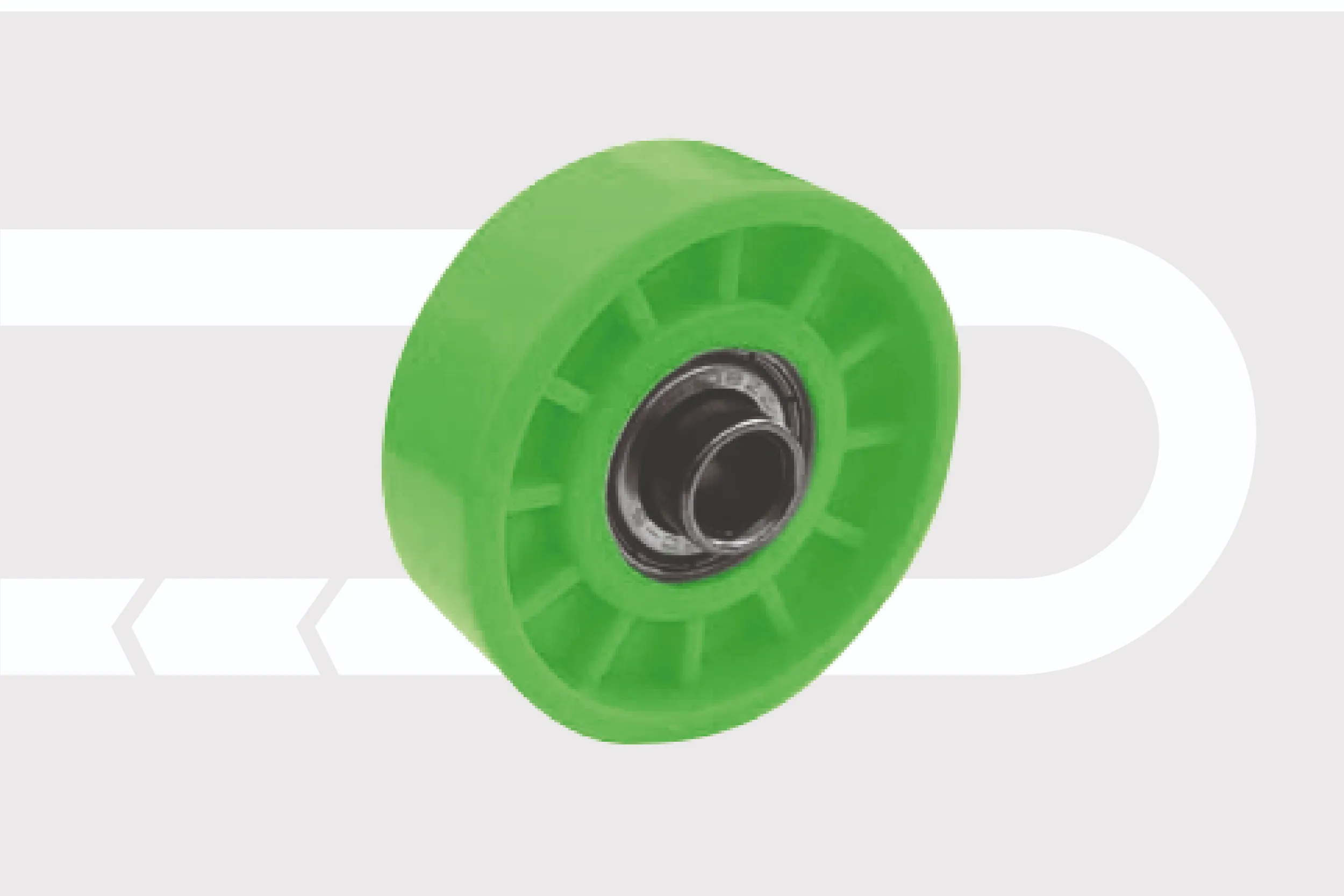

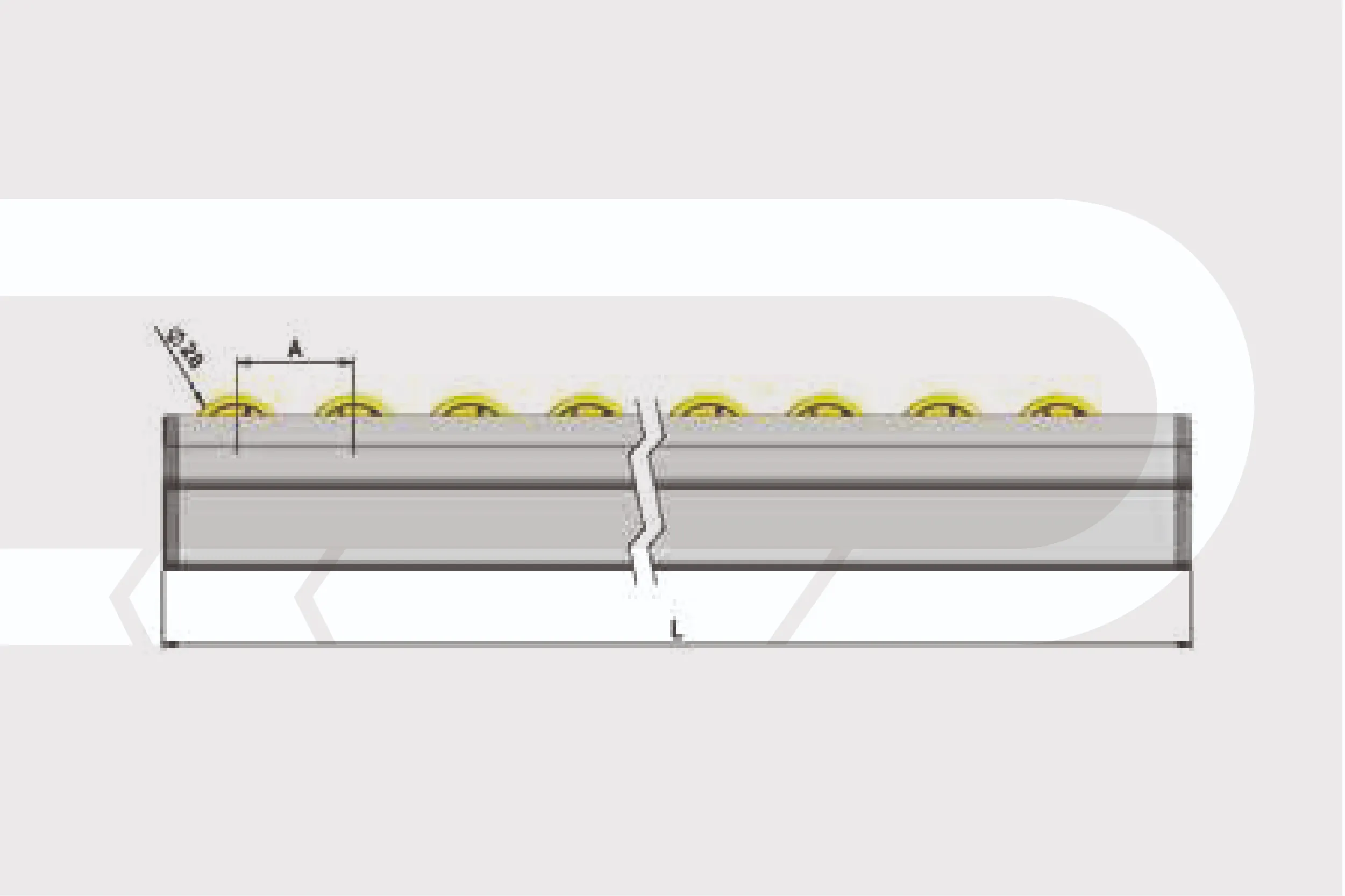

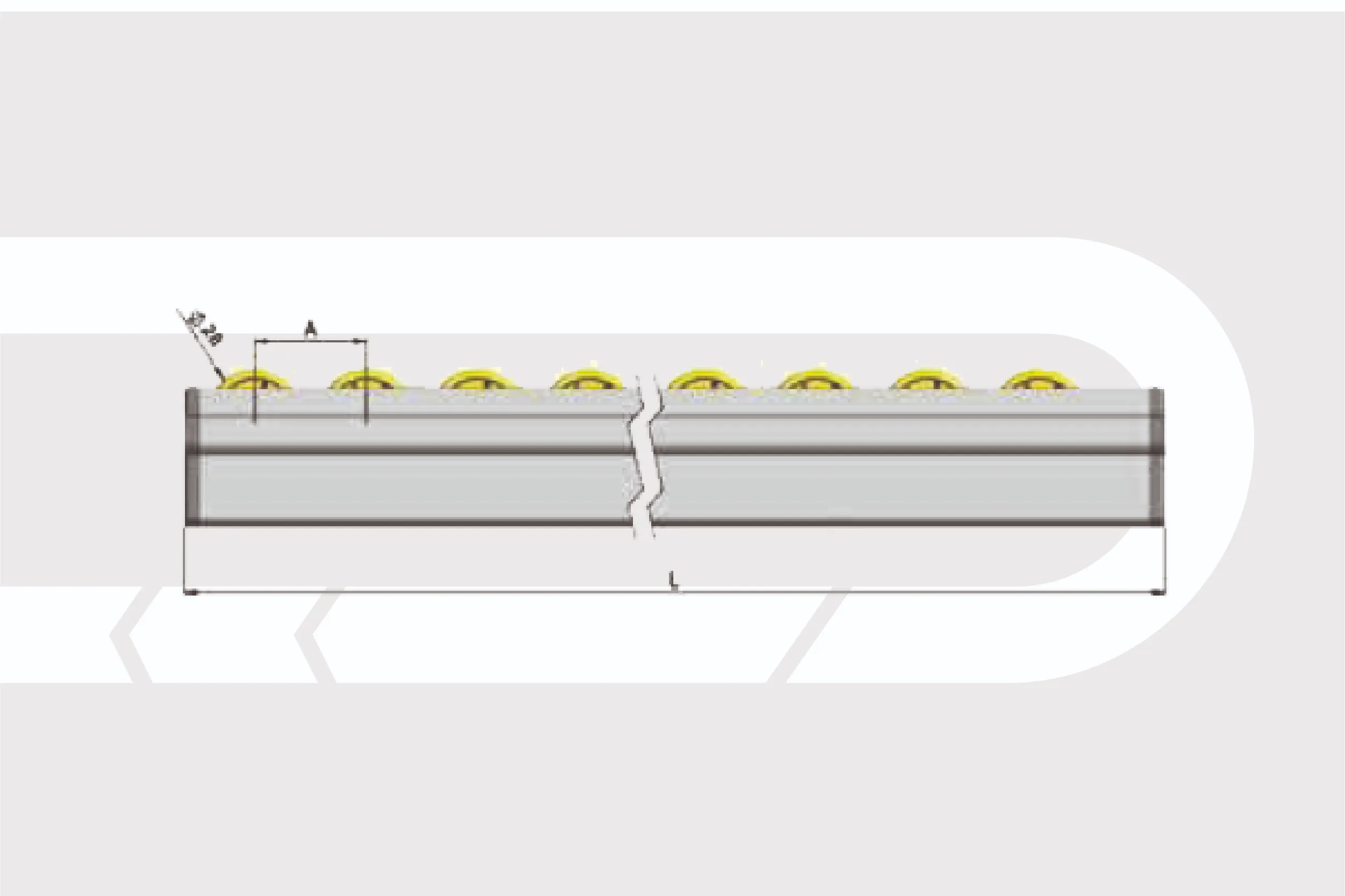

Conveline Rollers is a leading India’s CA-01-F gravity flow rack manufacturer, supplier, and exporter, known for delivering high-performance and durable material handling solutions. Designed to improve storage efficiency and streamline inventory flow, this model features a sturdy aluminum frame and ABS wheels that ensure smooth, low-friction movement of goods. The CA-01-F gravity flow rack is perfect for FIFO (first-in-first-out) systems, helping businesses manage stock rotation with ease. With a load capacity of 12.5 kg/m and a wheel pitch of 23.5 mm, it is perfect for lightweight to medium-duty applications in warehouses, distribution centers, and assembly lines. The use of corrosion-resistant materials guarantees long-lasting performance even in demanding environments. Conveline Rollers has engineered this gravity flow rack for quick installation, reduced labor effort, and increased productivity in fast-paced logistics operations. Whether it’s carton flow or component supply, the CA-01-F model offers reliability, consistency, and cost-effective handling of materials.

Features and Options:

- Frame - Aluminum

- Wheel - ABS

- load - 12.5 kg/m

- Wheel pitch - 23.5

Usage of CA-01-F - Gravity Flow Rack

- FIFO Inventory Management: Ideal for first-in-first-out inventory systems, ensuring older stock is used or shipped before newer stock.

- Warehouse Storage: Perfect for storing cartons, bins, and small-to-medium-sized items in warehouses and distribution centers.

- Production Line Support: Used in assembly lines for easy access to parts and components, improving workflow and efficiency.

- Retail Backroom Organization: Helps manage inventory in retail storage areas, keeping stock organized and accessible.

- Order Picking Efficiency: Enhances order picking speed by presenting products at the front for easy access.

- E-commerce Fulfillment: Widely used in e-commerce fulfillment centers for quick movement and sorting of products.

- Space Optimization: Maximizes vertical and horizontal space by using inclined lanes to move goods automatically.

- Cold Storage Facilities: Suitable for cold and refrigerated environments due to its durable aluminum frame and ABS wheels.

- Material Handling Lines: Efficient in handling lightweight items with a load capacity of 12.5 kg/m and wheel pitch of 23.5 mm.

- Lean Manufacturing Systems: Supports lean practices by reducing waste, improving organization, and boosting productivity.

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

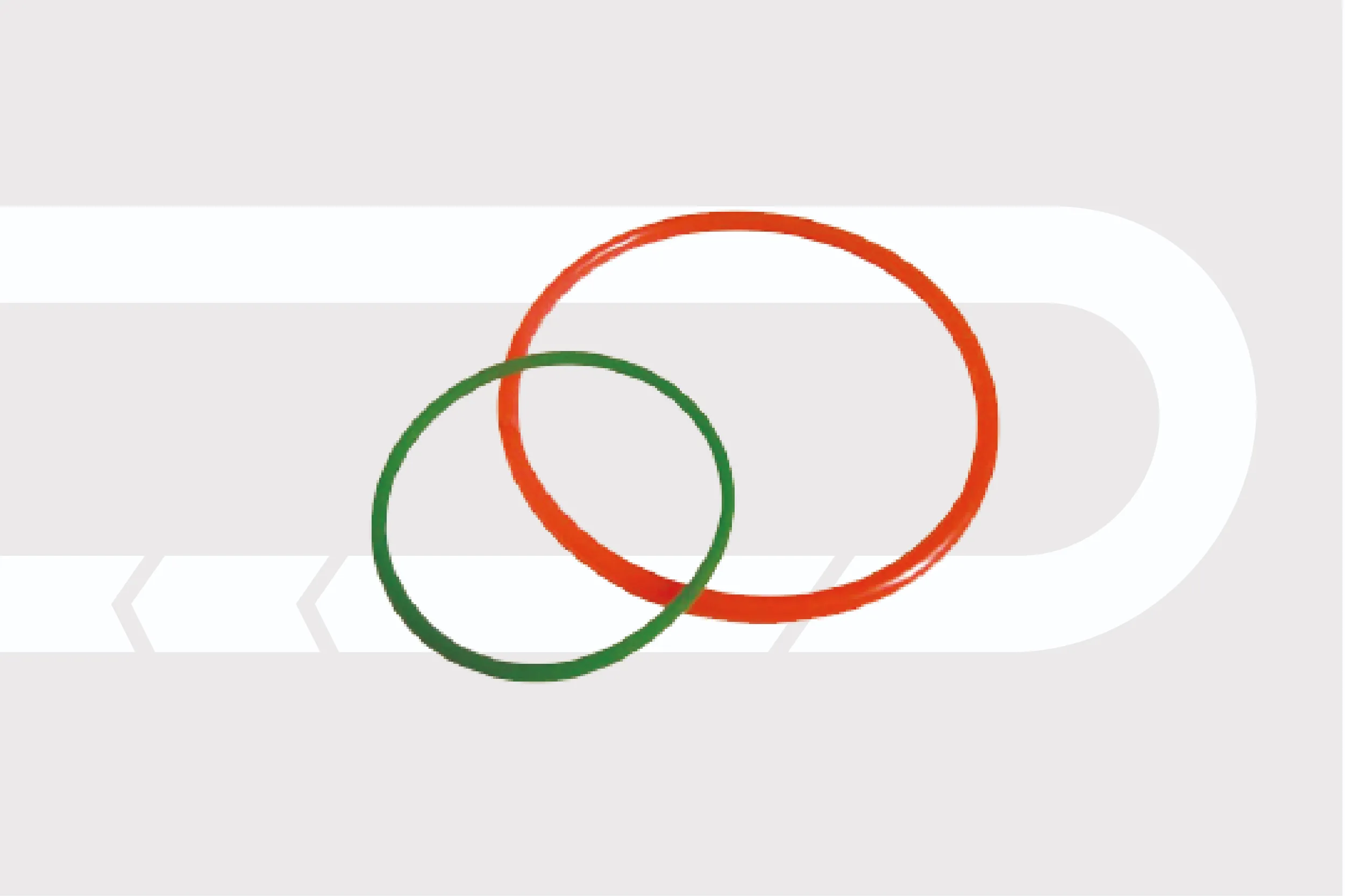

Accessories Range :

Frequently Asked Questions

Frequently Asked Questions

1. What is a Gravity Flow Rack System?

A gravity flow rack system uses inclined shelves with rollers or wheels to allow products to move forward automatically, using gravity.

2. How does a Gravity Flow Rack work?

Products are loaded from the back and move forward to the picking face, providing first-in, first-out (FIFO) inventory management.

3. What types of products can be stored in Gravity Flow Racks?

These racks are ideal for cartons, bins, boxes, and lightweight packaged goods.

4. What industries use Gravity Flow Rack Systems?

They are commonly used in warehousing, manufacturing, e-commerce, retail, pharmaceuticals, and food distribution.

5. What are the benefits of using Gravity Flow Racks?

They improve space utilization, enhance picking efficiency, support FIFO, and reduce labor costs.

6. Can Gravity Flow Racks be customized?

Yes, they can be customized based on wheel pitch, load capacity, rack dimensions, and material type.

7. Are Gravity Flow Racks suitable for cold storage?

Yes, especially systems with aluminum frames and ABS wheels that withstand cold environments.

8. What is the typical load capacity of a Gravity Flow Rack?

Load capacity varies by model; for example, CA-01-F handles up to 12.5 kg/m.

9. How are Gravity Flow Racks installed?

They are modular and easy to assemble, with adjustable levels to fit different product sizes.

10. Are these racks compatible with automated systems?

Yes, they can be integrated with automated picking and warehouse management systems.