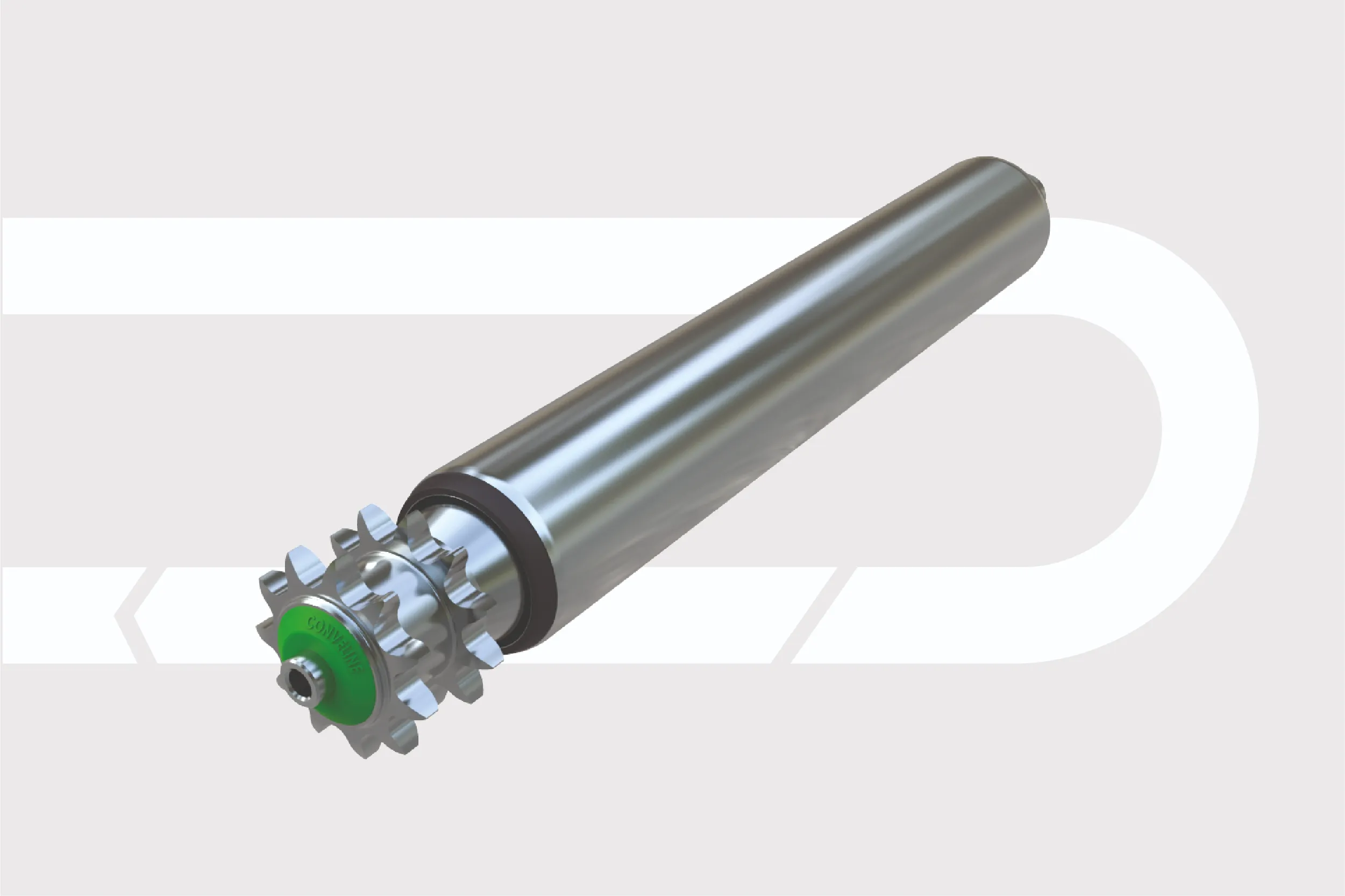

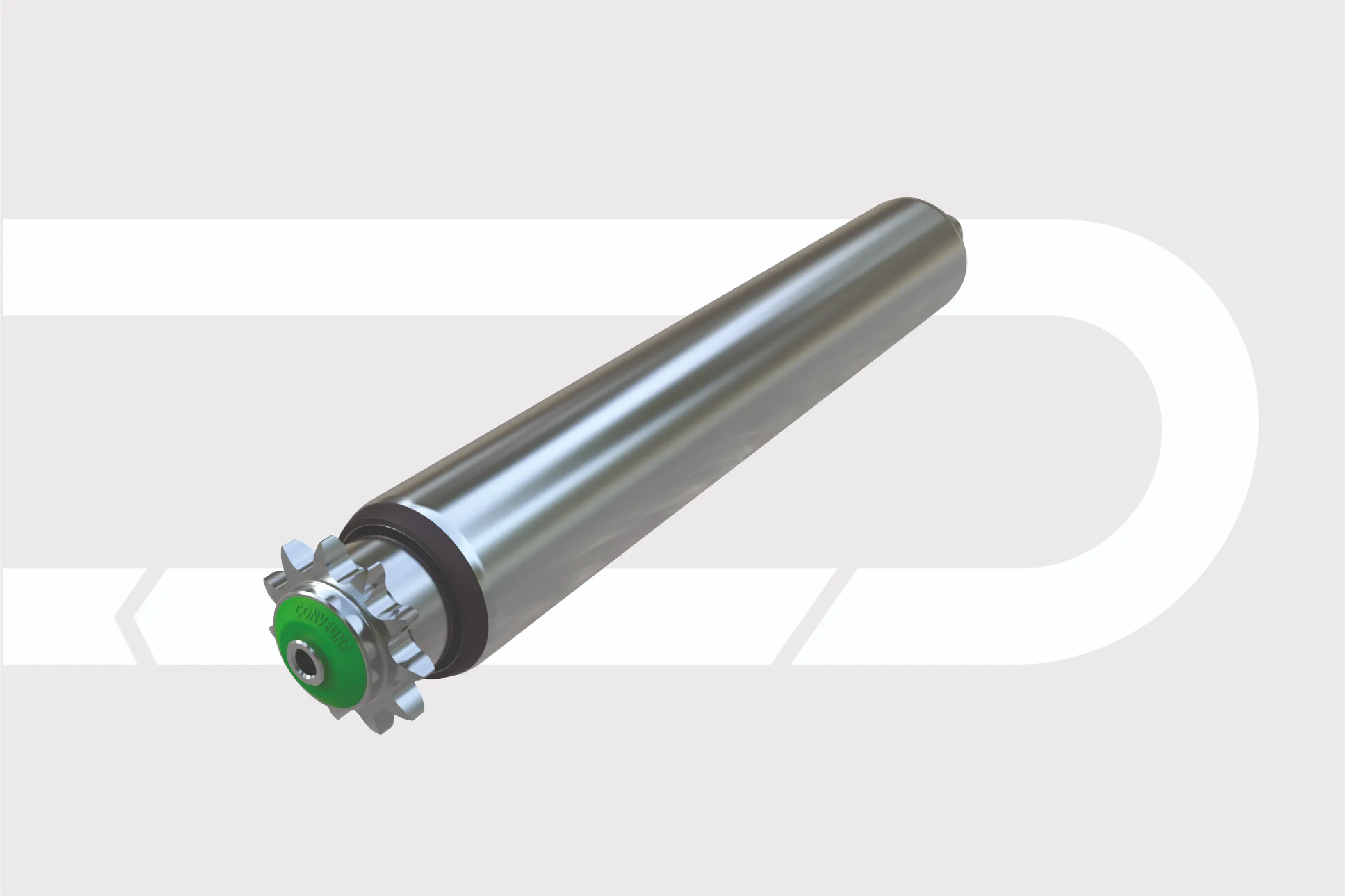

Accumulation Conveyor Roller

Accumulation rollers have the ability to remove drive in segments or zones to allow conveyed products to stop or collet at will. These rollers are used to hold or buffer products into area such as merges, sortation or palletizers. We manufacture rollers to suits size of 50mm, 60mm and 76mm.

Specifications:

| Series | Product Features | Diameter Range | Shaft Range |

|---|---|---|---|

| 1301 / 1302 | Polymer sprocket rollers, single or double sprocket, low running noise, polyamide bearing housing | 50 | 14 |

| 1303 / 1304 | Steel sprocket, single or double sprocket, polyamide bearing housing | 50 | 14 |

| 1305 / 1306 | Steel sprocket, adjustable torque, single or double sprocket, polyamide/steel bearing housing | 50, 60, 76 | 14, 15, 20 |

Features and Options:

- Suitable for wide range of application for Buffer or accumulation require

- Single drive with start/stop application suitable

- Single or double 14 teeth x 1/2” sprockets can be fitted (choice of steel or nylon sprockets)

- Mild steel and stainless steel options

- Stainless steel options available for all fixed driven conveyor rollers

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Roller Range :

Usage of Accumulation Rollers

Usage of Accumulation Rollers

Accumulation rollers are widely used in conveyor systems to control the flow of products and materials by allowing for the accumulation or buffering of items along the conveyor line. Some of the common applications of accumulation rollers include:

- Handling fragile or delicate products: Accumulation rollers are used to prevent products from colliding or bumping into each other, thereby reducing the risk of damage.

- Managing variable production rates: Accumulation rollers help to balance out the flow of products by allowing items to queue up and accumulate on the conveyor line during times of high production rates, and then release them at a controlled rate during times of slower production.

- Reducing pressure on downstream equipment: By controlling the flow of products, accumulation rollers can help to reduce pressure on downstream equipment, such as sorters and packagers, which can improve their efficiency and reduce the risk of breakdowns.

- Enabling manual sorting: Accumulation rollers can be used to provide a buffer zone where workers can manually sort products into different categories, without having to stop or slow down the conveyor line.

Frequently Asked Questions

Frequently Asked Questions

1. What is the maximum weight that can be accumulated on an accumulation roller?

The maximum weight that can be accumulated on an accumulation roller depends on the roller's specifications, such as its diameter and length. It is important to choose an accumulation roller that can handle the weight of the products being conveyed to ensure proper functioning and avoid damage to the system.

2. How does an accumulation roller function in a conveyor system?

An accumulation roller functions by allowing products to accumulate on the conveyor without stopping the conveyor's movement. The rollers are designed to rotate freely when products are not present, but when a product accumulates, the roller stops rotating, which allows the products behind it to continue moving forward until space is available for the accumulated product to continue.

3. Can accumulation rollers be used for heavy-duty applications?

Yes, accumulation rollers can be used for heavy-duty applications. However, it is important to choose a roller that is specifically designed to handle heavy loads and can withstand the wear and tear of continuous use.

4. How can I ensure proper maintenance of accumulation rollers?

Regular cleaning and inspection are essential to ensure the proper maintenance of accumulation rollers. Dirt and debris can accumulate on the rollers, which can affect their functioning, so it is important to keep them clean. Additionally, it is important to inspect the rollers regularly to check for any signs of wear and tear or damage that could affect their performance.

We Export Accumulation Rollers Worldwide

We Export Accumulation Rollers Worldwide

Russia | USA | UAE | Australia | Malaysia | France | Kuwait | Saudi Arabia | Singapore | Switzerland | Qatar | South Korea | Bangladesh | Czech Republic | The Netherlands | Kazakhstan | Nigeria | Vietnam | Oman | Thailand | Mexico | Argentina | Brazil | Canada | India | Japan | Indonesia | New Zealand | Egypt | South Africa | Philippines | Turkey | Greece | Norway | Sweden | Portugal | Spain | Italy | Belgium | Poland | Ireland | Austria | Denmark | Finland | Israel | Iran | Iraq | Lebanon | Jordan | Syria | Libya | Algeria | Morocco | Sudan | Kenya | Uganda | Zimbabwe | Angola | Cambodia | Nepal | Sri Lanka | Myanmar | Afghanistan | Ethiopia | Ghana | Peru | Chile | Bolivia | Honduras | Guatemala | Ecuador | Paraguay | Uruguay | Serbia | Croatia | Bosnia and Herzegovina | Iceland | Luxembourg | Belarus | Ukraine | Lithuania | Latvia | Estonia | Georgia | Armenia | Azerbaijan | Yemen | Bahrain | Cyprus | Maldives | Brunei | Bhutan | Laos | Mauritius | Seychelles | Barbados | Jamaica | Trinidad and Tobago | Fiji | Solomon Islands | Micronesia | Vanuatu | Malta | Albania | Moldova | Slovenia | Macedonia | Montenegro | Kosovo | Suriname | Guyana | Belize | Nicaragua | El Salvador | Panama | Costa Rica | The Bahamas | Eswatini | Botswana | Namibia | Lesotho | Zambia | Malawi | Rwanda | Burundi | Djibouti | Eritrea | Somalia | Chad | Republic of the Congo | Democratic Republic of the Congo | Gabon | Equatorial Guinea | Guinea | Guinea-Bissau | The Gambia | Liberia | Sierra Leone | Togo | Benin | Burkina Faso | Ivory Coast | Senegal | Mali | Niger | Mauritania | Mozambique | Madagascar | Turkmenistan | Uzbekistan | Tajikistan | Kyrgyzstan | Palestine | East Timor | China | Pakistan | Hungary | Romania | Bulgaria | Slovakia | Venezuela | Colombia