Gravity Flow Rack Manufacturer

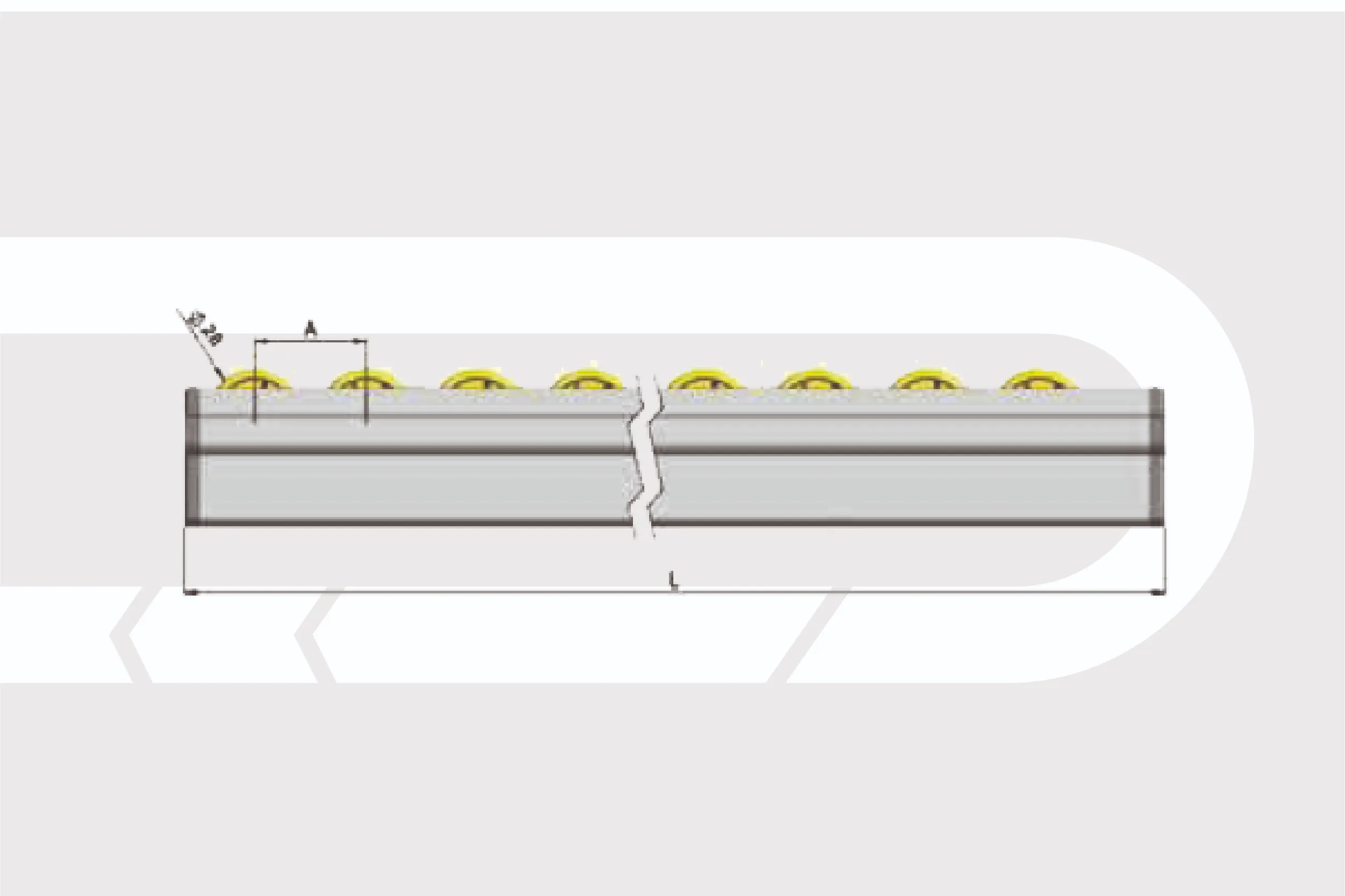

Conveline Rollers is one of India’s leading manufacturers, suppliers, and exporters of gravity flow racks. These innovative storage systems, also called carton flow racks or dynamic flow racks, are designed to enhance inventory efficiency in warehouses, distribution centers, and production facilities. By using inclined roller lanes, gravity automatically moves stored items from the loading side to the picking side. This ensures that products are always accessible and replenishment happens smoothly, following a first-in-first-out (FIFO) method.

Conveline Rollers is a manufacturer of high-quality gravity flow rack systems with durable frames and precision-engineered rollers to handle various load types. These racks are highly adaptable and can be configured to fit different sizes of cartons, bins, or totes. With a modular design, they can be seamlessly integrated into existing storage systems.

The gravity flow rack is built to reduce picking time, minimize handling errors, and improve warehouse productivity. Their ability to keep stock visible and within reach helps workers easily locate items, reducing search time and improving order fulfillment speed. Gravity flow racks save valuable floor space by using vertical and horizontal storage more efficiently. Conveline Rollers ensures every system is made to meet specific storage needs, enhancing overall supply chain performance.

Features and Options:

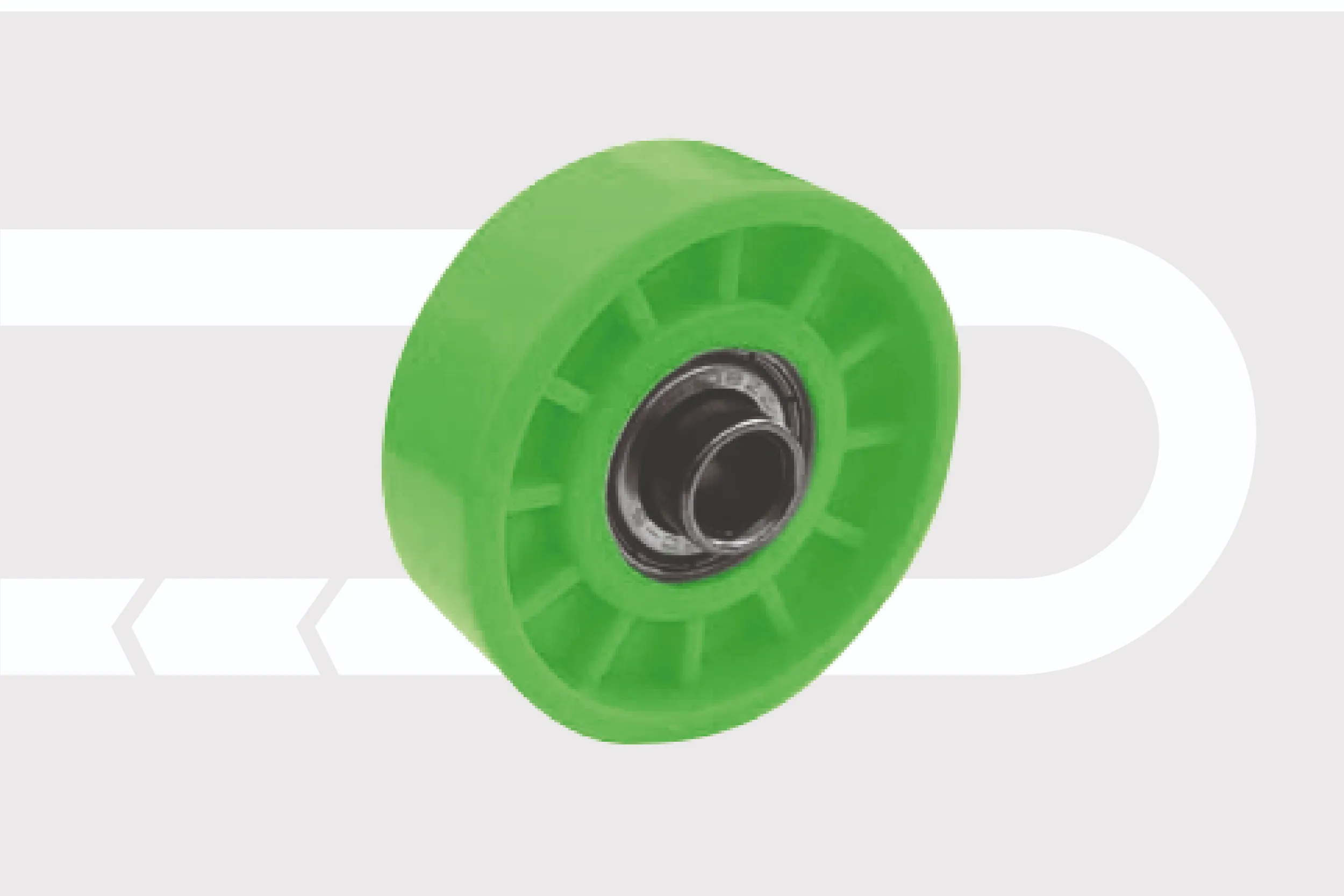

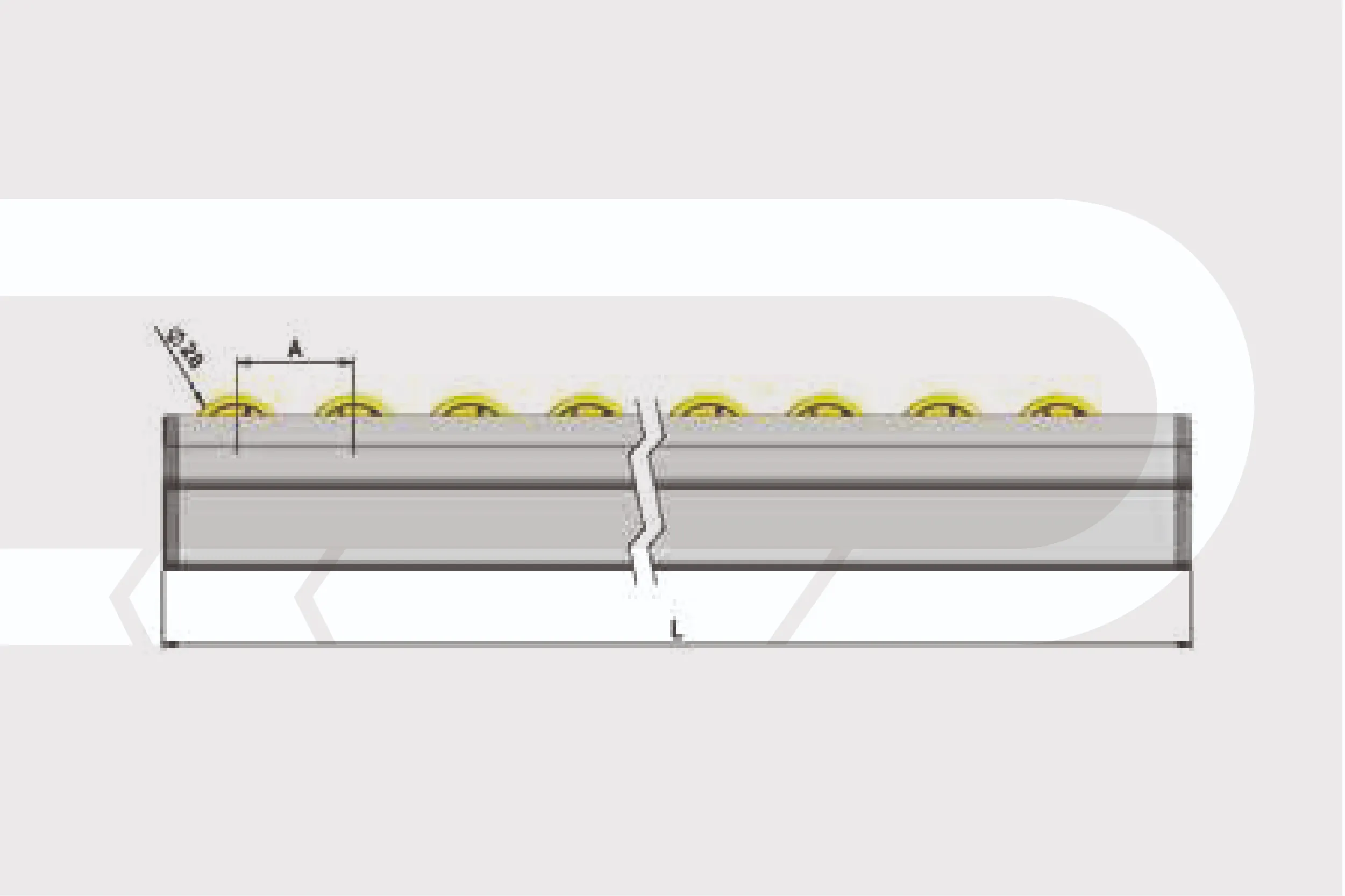

- Frame - Aluminum

- Wheel - ABS

- Load - 12.5 kg/m

- Wheel pitch - 23.5

Usage of Gravity Flow Rack

- Ideal for storing and managing inventory in warehouses and distribution centers.

- Commonly used in picking and packing stations for fast-moving consumer goods (FMCG).

- Perfect for first-in-first-out (FIFO) inventory rotation in perishable goods and pharmaceuticals.

- Efficient in automotive and spare part storage for quick part identification.

- Helps streamline the supply chain in manufacturing plants for component storage.

- Utilized in cold storage facilities where efficient space use and accessibility are critical.

- Suitable for storing packaged goods in retail and supermarket back-end storage.

- Used in beverage and food industries for sorting and organizing bottles or cartons.

- Reduces labor time and walking distances during order picking and restocking.

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Accessories Range :

Frequently Asked Questions

Frequently Asked Questions

1. What is a Gravity Flow Rack?

A gravity flow rack is a storage system that uses inclined roller tracks to allow items to move from the loading end to the picking end using gravity.

2. How does a Gravity Flow Rack work?

Products are loaded from the rear side of the rack and roll forward to the front for picking, following the First-In-First-Out (FIFO) method.

3. Where are Gravity Flow Racks commonly used?

They are widely used in warehouses, distribution centers, supermarkets, food & beverage industries, and pharmaceutical storage facilities.

4. What are the main benefits of using Gravity Flow Racks?

They help increase storage efficiency, reduce handling time, improve stock rotation, and enhance order-picking speed.

5. Can Gravity Flow Racks be customized?

Yes, Conveline Rollers provides fully customizable gravity flow racks to suit specific load sizes, warehouse layouts, and operational requirements.

6. Are Gravity Flow Racks suitable for heavy loads?

They are best suited for lightweight to medium-weight cartons or bins. For heavy loads, specially reinforced systems can be designed.

7. What materials are used in Gravity Flow Racks?

High-quality steel frames and durable plastic or metal rollers are typically used for strength and long-term use.

8. Is installation of Gravity Flow Racks complicated?

No, they are modular and easy to install. Conveline Rollers offers support for smooth setup and integration.

9. How do Gravity Flow Racks support FIFO inventory management?

Items placed first are picked first as they naturally roll to the front, ensuring accurate stock rotation and reducing spoilage.

10. Can Gravity Flow Racks be integrated with other storage systems?

Yes, they can be seamlessly combined with static racks, pallet racking, and automated picking systems.