O Ring Rubber Mould Manufacturer

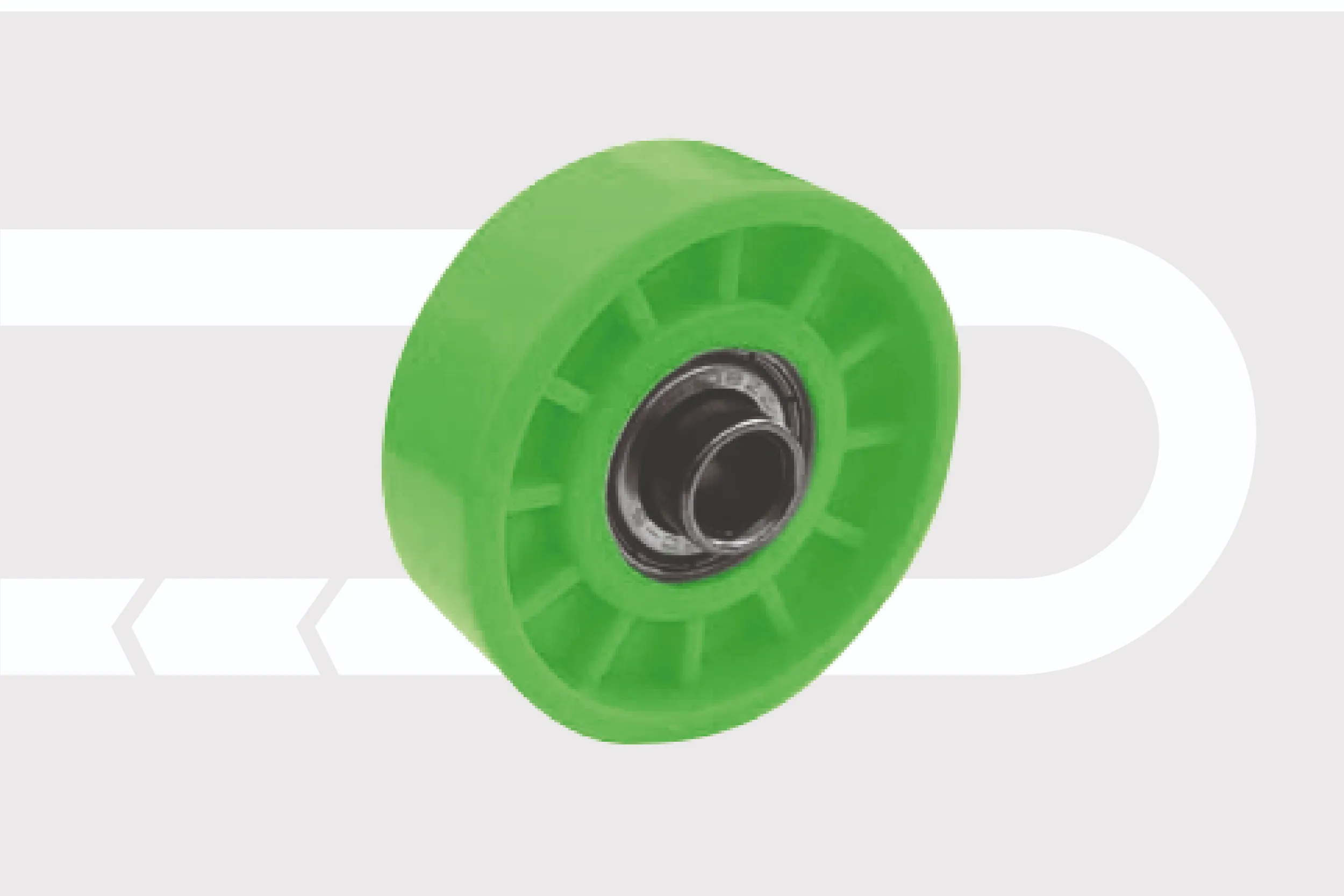

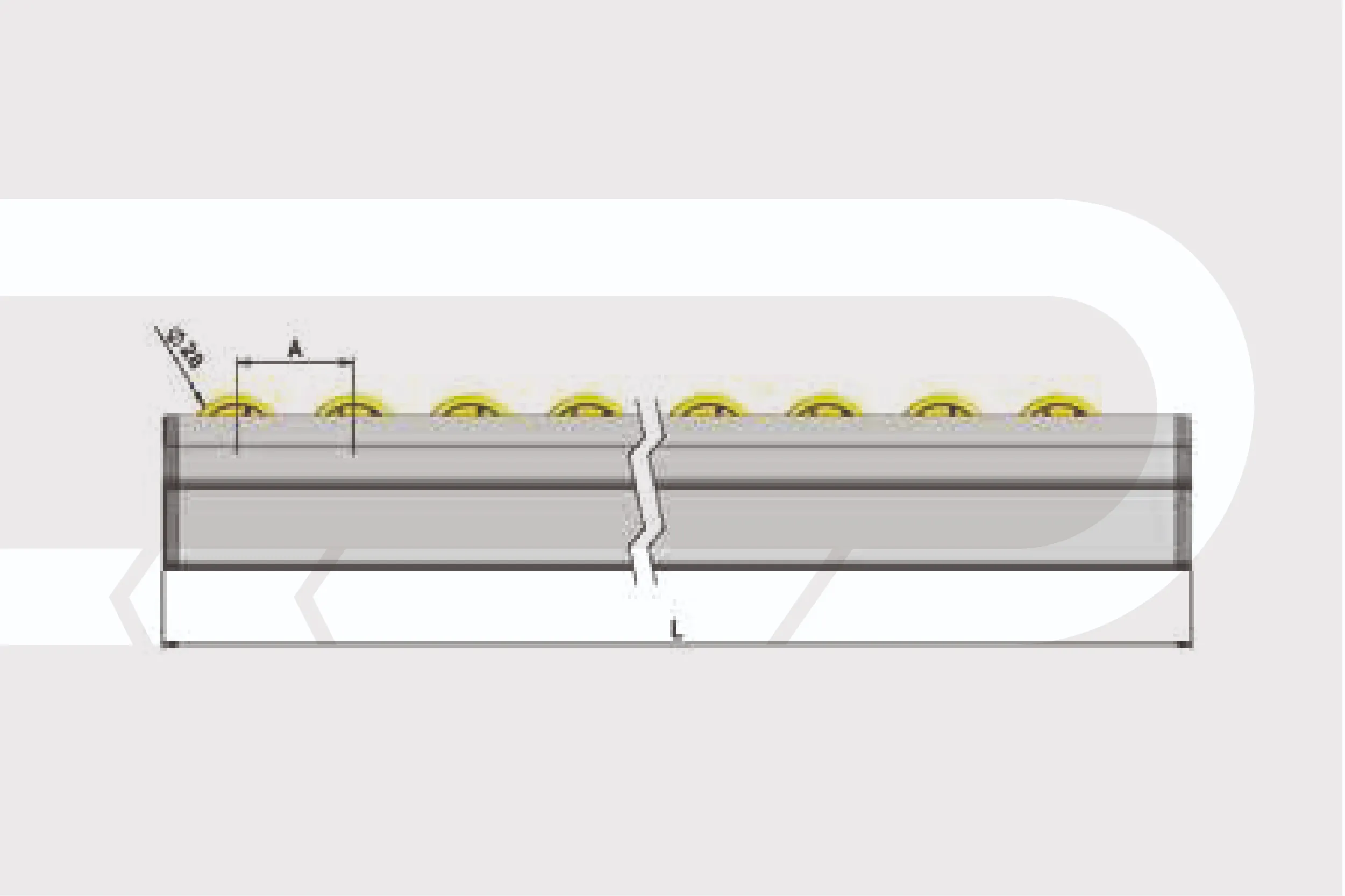

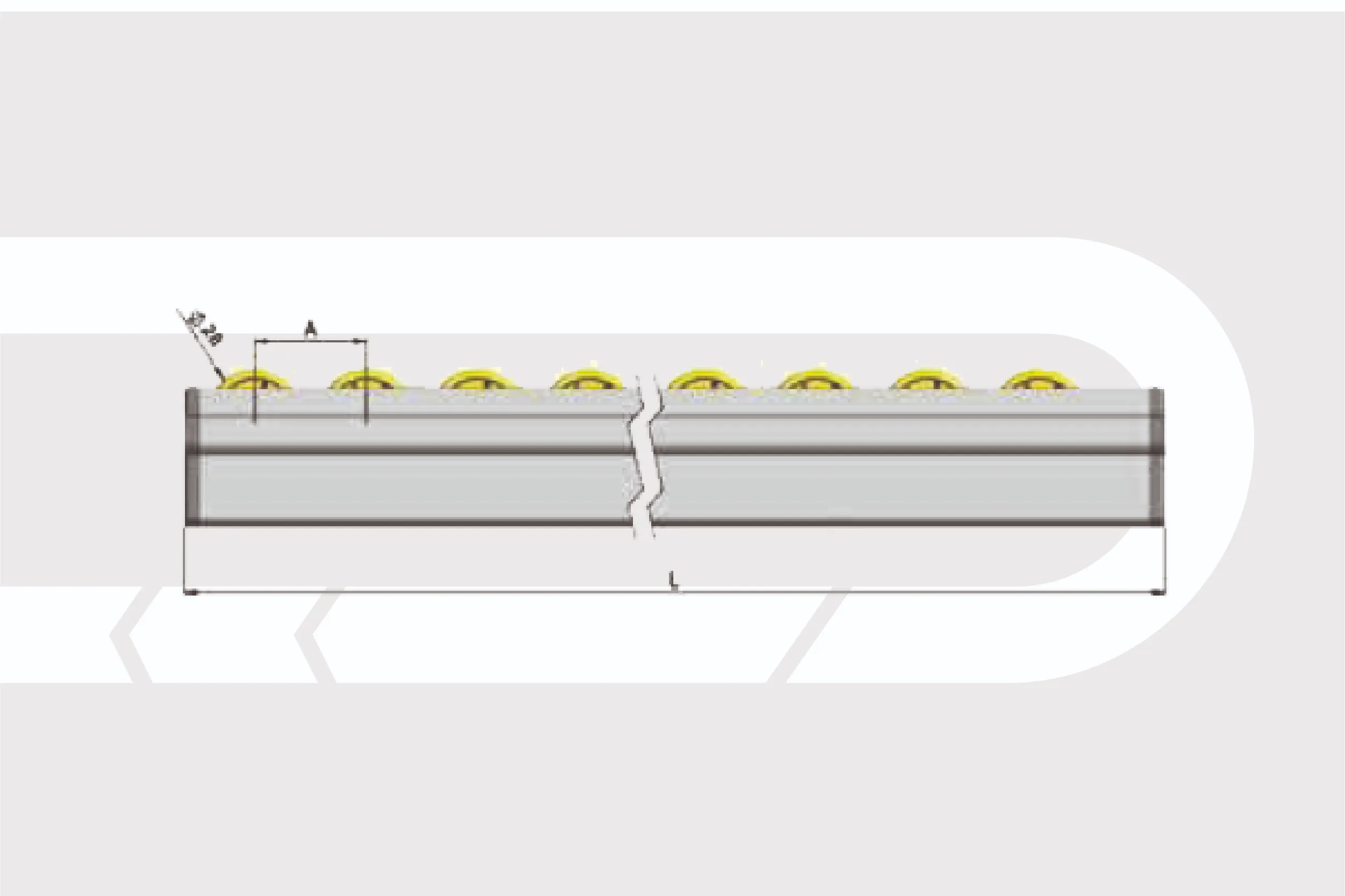

Conveline Rollers is recognized as one of India’s leading manufacturers, suppliers, and exporters of CA-01-F – O Ring Moulds, offering reliable sealing solutions for a wide range of industrial applications. Designed for precision, durability, and performance, these o ring rubber molds are essential components used in conveyor systems and various mechanical assemblies. Conveline Rollers is a manufacturer of o ring molds using high-quality polyurethane (PU) material in green color with a molded 5mm diameter, providing optimal flexibility and strength. With a recommended roller pitch of 75mm, these o ring rubber mould are perfectly suited for efficient and consistent motion transmission. Rubber o ring manufacturers from Conveline Rollers are built to handle both static and dynamic applications. They are commonly used in settings where components are either stationary or in relative motion, such as in moving rollers or conveyor assemblies. Their robust construction allows them to withstand high pressure, often up to several thousand psi, making them ideal for sealing and motion control tasks in demanding environments. Due to their simple yet highly effective design, o ring rubber molds are among the most widely used and trusted sealing devices in machinery design today.

Available in various standard metric and inch sizes, Conveline’s o ring rubber molds are customized to meet the performance demands of multiple industries. Each o ring is engineered with a consistent inner diameter and cross-sectional thickness, ensuring a precise fit and function. Known for their high elasticity, superior tensile strength, and long-lasting performance, Conveline Rollers' rubber o rings are trusted across diverse sectors such as the automotive, dairy, textile, paper, chemical, and heavy engineering industries.

Features and Options:

- Type - Molded 5mm dia,

- Material - PU, green

- Suggested roller pitch - 75mm

Usage of CA-01-F - Rubber O Ring

Used for sealing gaps between parts in conveyor systems to prevent leakage and contamination.

- Ideal for static and dynamic applications: Suitable for scenarios involving relative motion or vibration.

- High-pressure sealing: Applied in machinery for sealing high-pressure environments up to several thousand psi.

- Powered conveyor systems: Commonly used in rollers to transmit drive force in powered conveyor systems.

- Automotive industry: Utilized for gaskets and various sealing applications.

- Chemical industry: Perfect where resistance to abrasion and harsh elements is essential.

- Dairy and food processing: Used for their hygienic and flexible sealing properties.

- Textile and paper machinery: Found in machines to prevent fluid and dust intrusion.

- Drive systems: Helps maintain consistent motion and alignment.

- Conveyor rollers: Acts as a buffer or spacer, reducing wear and improving durability.