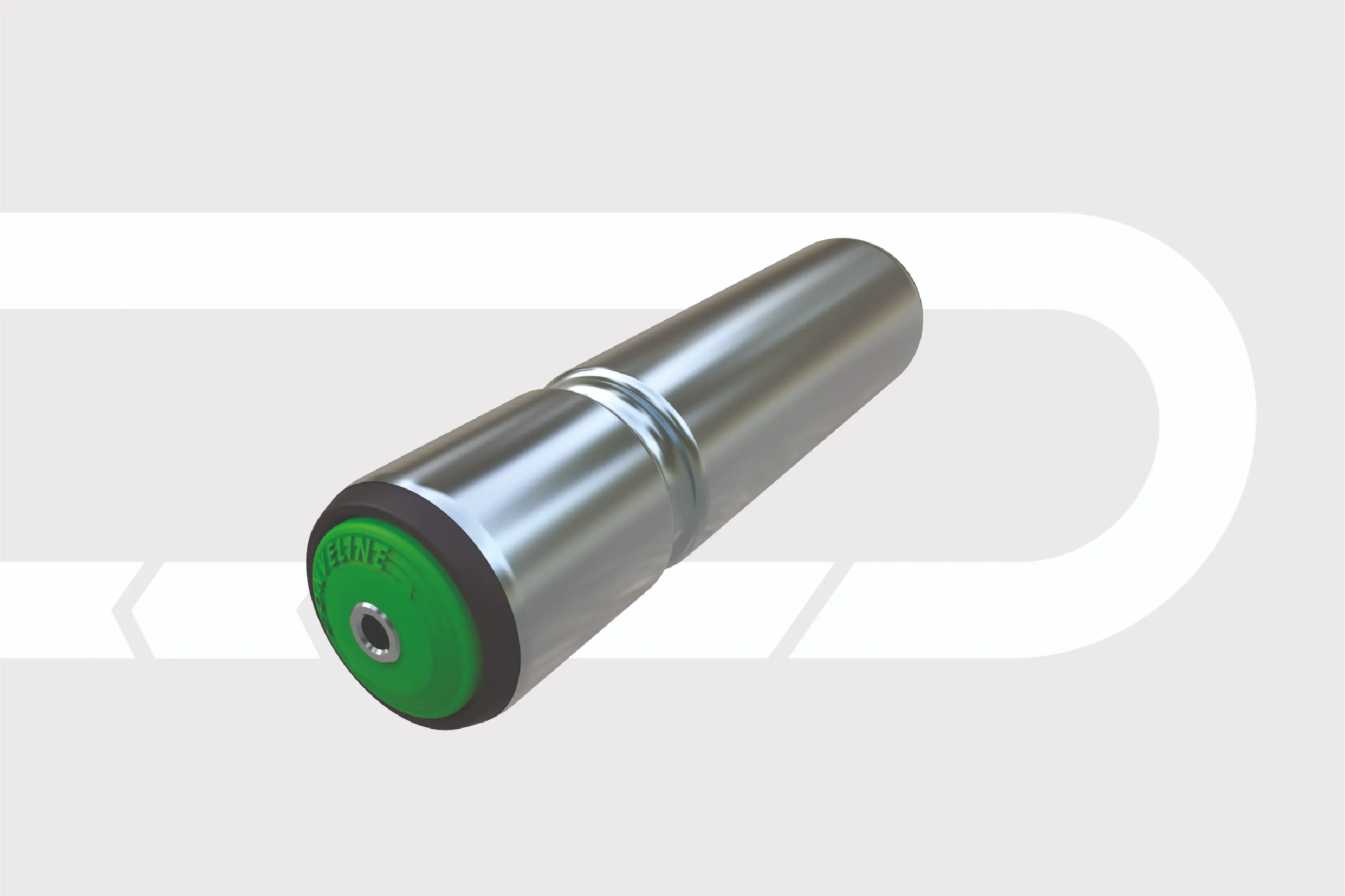

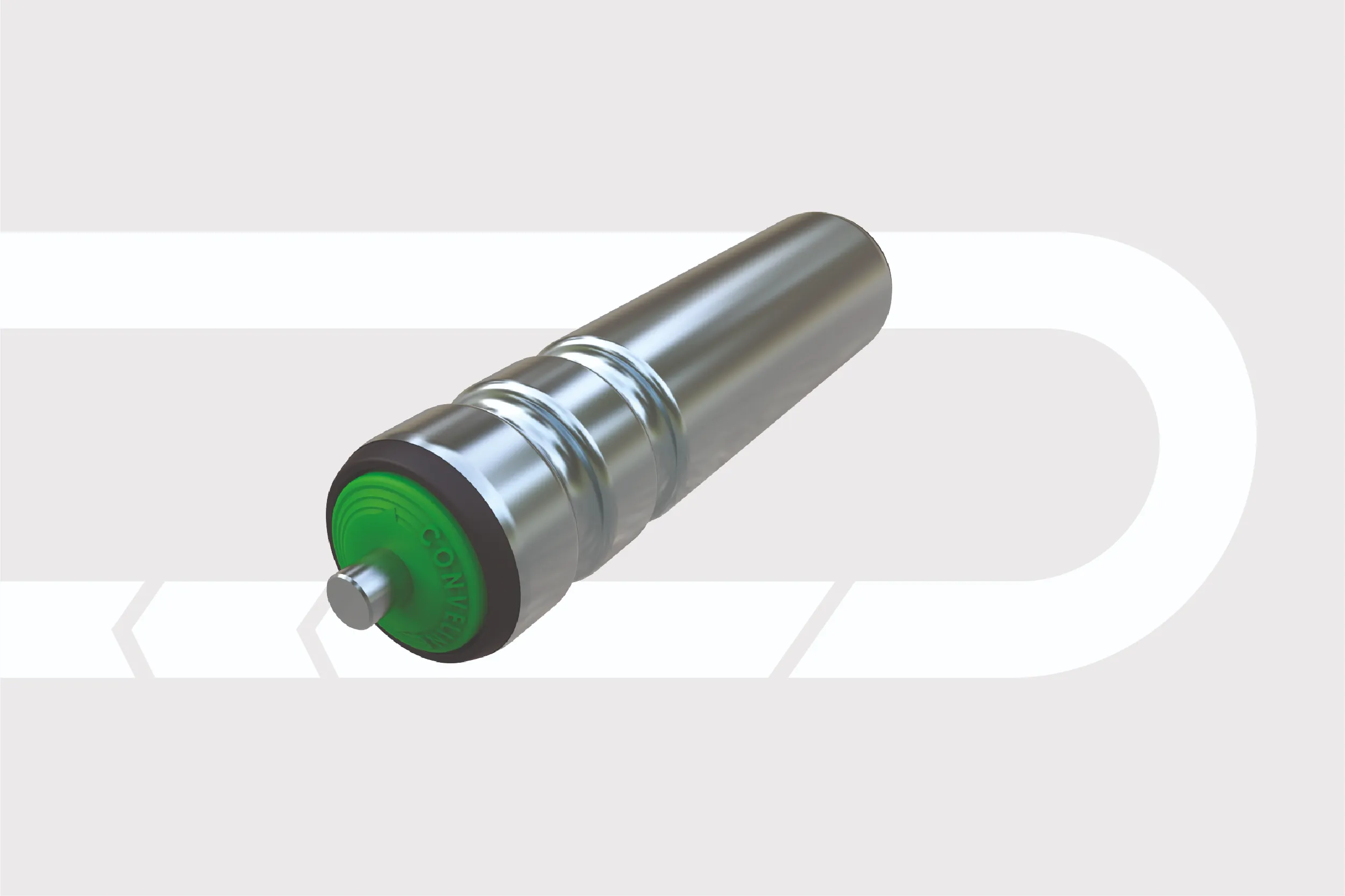

Grooved Conveyor Roller

Grooved Driven Conveyor rollers offer the most economical and simplest powered method form of transporting loads from the one point to another point.

Grooved rollers for lineshaft conveyors are available with zinc plated steel tubes and stainless steel tubes in a choice of tube diameters of 50mm.

Our grooved conveyor rollers are grooved suit varying diameters of round drive belts and available for use in either lineshaft or 24V DC Motorised Roller conveyors.

Roller can be single or multi grooved to suit varying diameters of round belts. Positions can be identified at time of enquiry.

Specifications:

| Series | Product Features | Diameter Range | Shaft Range |

|---|---|---|---|

| 1201 / 1202 | O belt rollers, single or double groove light/medium duty conveyor rollers, custom made groove | 50 | 11, 14 |

| 1203 | O belt pulley rollers, light/medium duty conveyor rollers | 50 | 11, 14 |

Features and Options:

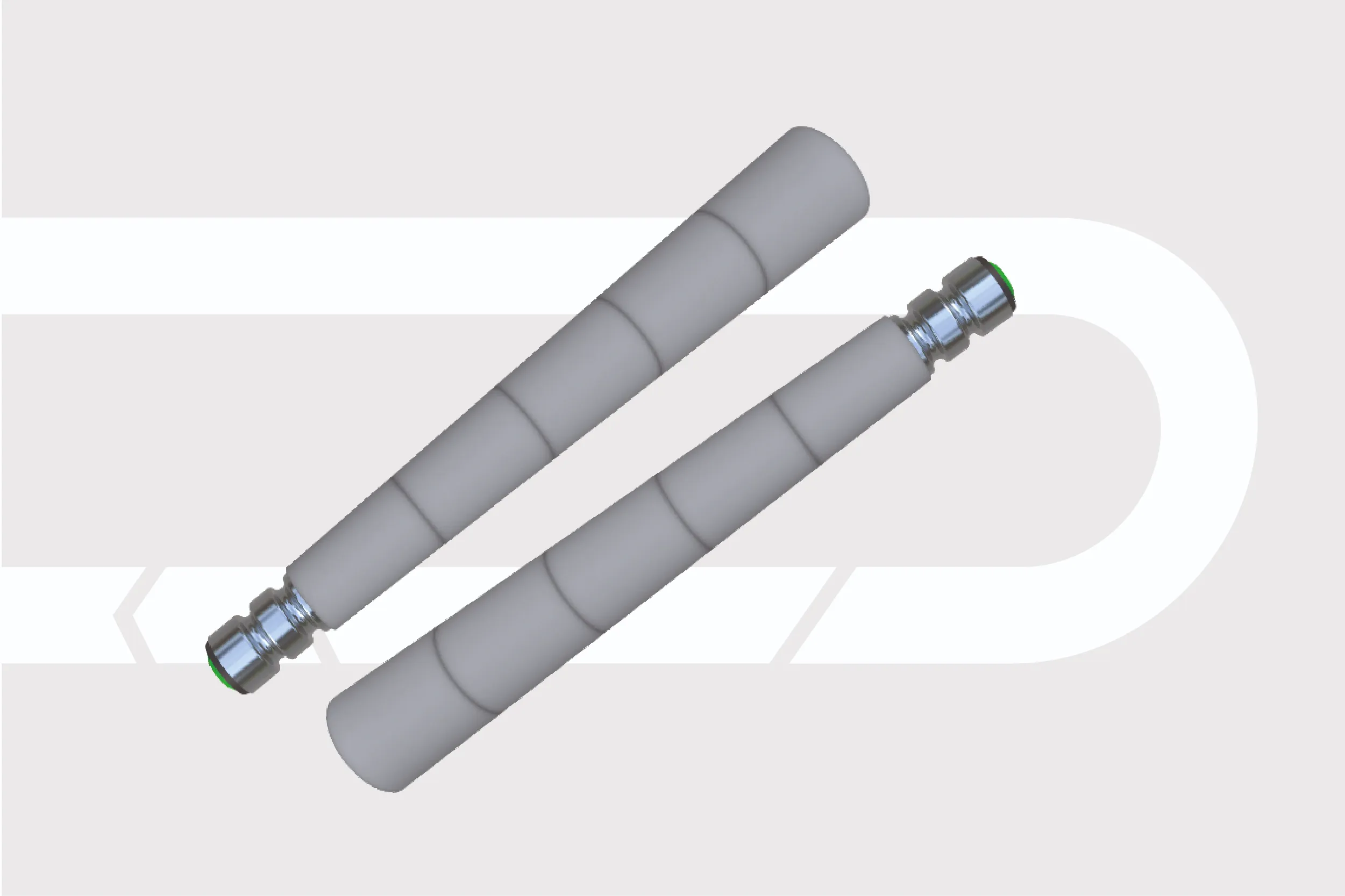

- Single and Double Grooves option

- Light and medium duty driven roller fitter with nylon O ring sprocket

- Lineshaft and 24V DC motorized rollers conveyors

- Mild steel, stainless steel and plastic options

- Stainless steel options available for all fixed driven conveyor rollers

Why Choose Conveline

manufacturing Area

Manufacturing Capacity Yearly

Manufactured in India

manufacturer of Conveyor Rollers

Roller Range :

Usage of Grooved Rollers

Usage of Grooved Rollers

Grooved rollers are a type of conveyor roller that features a series of grooves or channels cut into the surface of the roller. These grooves serve several purposes, including:

- Improved traction: The grooves help to improve traction and prevent slippage between the conveyor belt and the roller, especially when moving heavy or bulky items.

- Directional control: The grooves can be used to help direct the movement of the conveyed material, keeping it centered and preventing it from veering off course.

- Reduced noise: The grooves can help to reduce noise levels during operation, making them a good choice for applications in noise-sensitive environments.

- Improved flexibility: Grooved rollers can be used in a variety of conveyor configurations, including curved or spiral conveyors, providing greater flexibility in conveyor design.

Frequently Asked Questions

Frequently Asked Questions

1. What materials are grooved rollers typically made of?

Grooved rollers can be made from various materials, including stainless steel, aluminum, and plastic, depending on the application and environment.

2. What are the benefits of using grooved rollers?

Grooved rollers provide improved traction and grip for materials being transported, reducing slippage and increasing efficiency. They also help to maintain proper alignment of the conveyed material.

3. What types of applications are grooved rollers best suited for?

Grooved rollers are commonly used in applications where materials need to be transported on an incline or decline, as well as in situations where there is a need for increased traction or grip, such as in food processing or packaging.

4. Can grooved rollers be customized to fit specific application requirements?

Yes, grooved rollers can be customized to meet specific requirements, including the groove size and pattern, material, and size. This allows for optimal performance in various applications.

How To Import Fixed Driven Rollers

How To Import Fixed Driven Rollers

Conveline Systems Pvt. Ltd is a leading manufacturer and supplier of high-quality Grooved Rollers in India. If you're interested in importing Grooved Rollers from Conveline Systems Pvt. Ltd, here are some steps you can follow:

- Contact Conveline Systems Pvt. Ltd: The first step to import gravity rollers from Conveline Systems Pvt. Ltd is to get in touch with them. You can either call them or send an email to their sales team. They will provide you with all the necessary information regarding their products and the importing process.

- Discuss your requirements: Once you have contacted Conveline Systems Pvt. Ltd, you should discuss your requirements with their sales team. They will help you choose the right type of gravity rollers based on your specific needs.

- Get a quotation: After discussing your requirements with Conveline Systems Pvt. Ltd, they will provide you with a quotation. This will include the price of the gravity rollers, shipping costs, and any other applicable fees.

- Place your order: If you're satisfied with the quotation provided by Conveline Systems Pvt. Ltd, you can place your order. They will then prepare your order and arrange for it to be shipped to your desired location.

- Receive your order: Once your order has been shipped, you will receive it at your desired location. Conveline Systems Pvt. Ltd ensures that their products are packaged safely to avoid any damage during transportation.

It is important to note that importing gravity rollers from Conveline Systems Pvt. Ltd may require compliance with certain import regulations and customs clearance procedures. It is recommended to seek the advice of a customs broker or freight forwarder to ensure a smooth importing process.